Modular Advocacy Program

The Modular Advocacy Program (“MAP”) is MBI's multiyear, multi-million dollar campaign to spur investment in, and promote the greater adoption of, the commercial modular construction industry.

In order to meet the growing needs of its members and the greater modular construction industry, MBI's MAP program will drive industry growth in the following areas:

- Influencing government legislation, regulations, procurement, programs, and codes.

- Creating new business opportunities for the industry.

- Expanding outreach efforts to developers, architects, and code officials.

- Attracting new employees to the industry, including non-traditional workers.

MBI, leveraging its growing international membership, plans to fund this program through a variety of initiatives.

Funding the Modular Industry's Most Important Initiative

Your company can support MBI's Modular Advocacy Program in three ways:

Sponsoring the MAP

Annual sponsorships for the MAP program are available for $1,000. If you're not buying Seals, this is an ideal way to show your support of MBI and contribute to MAP funding.

With your annual sponsorship, your company will receive:

- sponsor recognition and logo inclusion in every MBI printed piece (magazines, annual reports, event brochures),

- a dedicated eblast thanking each sponsor, AND

- a special thanks at the next World of Modular annual conference, including logo inclusion in the opening presentation.

MBI Seals

MBI Seals are 4-inch square stickers that are meant to be affixed inside each module that MBI member manufacturers produce. Each MBI Seal costs $20. These costs are intended to passed along to your customers, which means a net-zero cost to you.

Manufacturers - Order and affix an MBI Seal inside each module you manufacture.

Architects, Contractors, & Developers - Spec the MBI Seal on your future projects.

Fleet Owners – Ensure all new and existing units have the MBI Seal.

Voluntary Donations

If Seals and MAP sponsorship don't match your company's current objectives, support the MAP by making a voluntary donation in any amount.

In combination with the revenues from Seals and sponsorships, these donations will be used to grow and protect the commercial modular construction industry through government affairs advocacy, business development, expanding MBI's membership, and industry workforce development.

SUPPORTED BY

"BT Modular is proud to support MBI's Modular Advocacy Program and contribute to the continued growth of the modular industry. As a supplier of doors and hardware, we want to show support to the customers who have supported us over the years. Within the last 10+ years that I have been involved, I’ve had the privilege of watching this industry evolve and expand. It is exciting to see industry gain momentum and we are committed to playing our part in advancing its future. I encourage all suppliers to donate to this cause and support our friends in the industry."

Cortney Milbourne, VP of BT Modular

Advocating for Commercial Modular Construction

Led by the Modular Building Institute's government affairs director Alex Carmack, MBI's team of government affairs professionals is diverse, experienced, and well-connected on both the state and federal levels.

MBI also boasts a working committee of dozens of modular industry professionals that meets and advises MBI on existing legislative barriers, emerging issues, and opportunities to expand the adoption of modular and offsite construction.

Significant Wins for the Industry

MBI has recently contributed (entirely or in part) to a string of noteworthy victories for the modular building industry, including:

- Colorado is dispersing $40 million in grants to modular manufacturers to support affordable housing construction;

- Oregon passed a $20 million bill to support the use of modular to build affordable housing; I’ve been appointed to their finance committee to disperse the funds

- The International Code Council finalized and published its new MEP-focused building standard, MBI/ICC ANSI 1210;

- The Canadian Mortgage Housing Corporation continues to fund its Rapid Housing Initiative with another $1.5 billion in funding, which includes specific support for modular construction;

- The National Nuclear Security Administration is finalizing recommendations to the US Department of Energy to utilize modular for over $10.5 billion in future projects;

- A New York state bill that would have required NYC-licensed workers to oversee work in modular factories was defeated for the fourth consecutive year;

- Washington state fully adopted the use of third-party inspection agencies for plan reviews;

- Virginia became the first state to formally adopt MBI/ICC ANSI 1200/1205; and

- Utah has just voted in favor of creating a state modular program.

Your company's support of the MAP is crucial to MBI's ability to achieve these results.

Modular Building Institute Defeats Davis-Bacon Act Expansion

The Modular Building Institute, with the support of its members, has defeated the US. Dept. of Labor's Davos-Bacon Act expansion, and the stakes for the modular construction industry could not have been higher.

Creating New Business Opportunites

MBI works with governmental and non-governmental organizations around the world to make connections and highlight the abilities of commercial modular construction. In doing so, MBI routinely engages, supports, and advises state, provincial, and municipal agencies to create opportunities for its members to contribute to well-funded and much-needed modular construction projects. These efforts would not be possible without MBI's involvement, and MBI's involvement wouldn't be possible without support from the industry itself.

Recent efforts by MBI to create opportunities for the industry have included:

FEMA Announces Hawaii Housing Plan Using Modular Construction

The plan marks is a major change for FEMA as it begins to incorporate modular housing into its disaster-relief options.

ICC/MBI Standards 1200 & 1205 Provide Foundation for Utah's First-Ever State Modular Program

Utah becomes the second state in the country, following Virginia, to fully adopt ICC/MBI standards 1200 and 1205.

Colorado Announces Modular Housing Loans to Create Up to 4,755 More Housing Units Per Year

Gov. Jared Polis just announced funding to support the growth of eight modular housing manufacturers across Colorado.

Broadening MBI's Membership with Architects and Engineers

As public and private organizations continue to turn toward modular buildings for the many benefits they provide, architects and engineers are being increasingly called upon to design buildings that will be built using prefabricated or modular construction. As the world's largest trade association for the commercial modular construction industry, MBI is reaching out to design professionals to both bolster its membership and provide these design professionals with the promotion, resources, and connections they need to succeed in modular design and construction.

Recent design-focused resources have included:

From a Basement Office to a Team of Modular Experts

“The modular offsite construction project type actually found EVstudio because of our company’s integrated multidisciplinary approach,” Dalvit said, which led the company to develop a focused design studio around that project type.

Modular Architecture: Thinking Outside of the Box with Sara.Ann Logan

It might seem strange to use the term “out of the box thinking” in the modular construction world, but when you’re talking about Sara.Ann Logan, the VP of design at Volumetric Building Companies, the phrase fits like a glove.

Is Modular + Scattered Sites a Solution to the Affordable Housing Crisis?

By utilizing modular construction, architect Dean Dovolis and his team were able to design houses that fit into their respective neighborhoods while keeping construction costs to a minimum.

Developing Tomorrow's Workforce

The Modular Building Institute (MBI) developed the MBI Learning Center with the goal of introducing learners to the commercial side of modular construction – an innovative and exciting modern method of construction.

The first course, Introduction to Commercial Modular Construction, discusses the modular building process compared to traditional site-built construction and is designed to help learners understand the terminology and concepts of modular building, including client needs, design, fabrication, transportation, and installation.

Other recent workforce development efforts and coverage have included:

MBI-Sponsored Design Competitions

These annual competitions—hosted by the University of New Brunswick's Off-Site Research Centre and presented by the Modular Building Institute (MBI)—showcase student design innovation in modular, prefabricated, panelized, and other types of off-site construction.

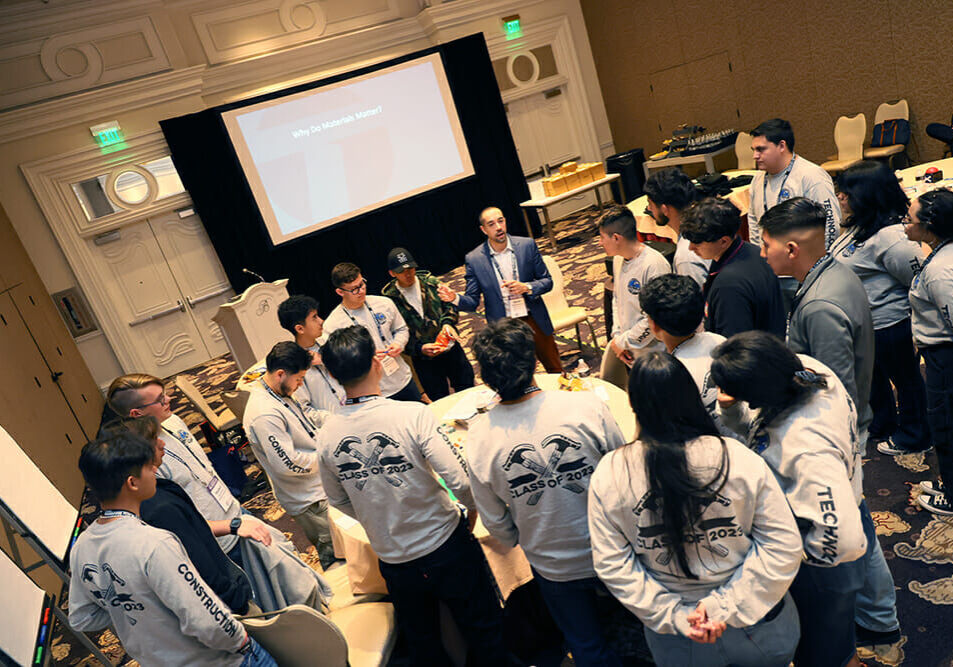

Welcoming the Industry’s Rising Stars to the World of Modular

Each year, MBI hosts dozens of high school students from regional trade-focused schools at its World of Modular conference. Students take part in dedicated workshops, meet with exhibiting companies, and receive instruction from industry leaders.

Is Your Company a “Destination Employer?” These Four Are

Autovol, Momentum Innovation Group, Signature Building Systems, and Modern Building Systems have been working hard to attract workers, particularly young workers, to their companies through a combination of culture and actively reaching out to students to make them aware of opportunities.

MBI Needs You to Support the MAP

Full member support of the Modular Advocacy Program will be critical to MBI's goals in 2024 and beyond. And if your company has not yet joined MBI, now is the perfect time. With more resources than ever, the Modular Building Institute is helping to build the future of modular construction. Join us!

More from the Modular Building Institute

How Stack Modular Is Using AI to De-Risk Mid- to High-Rise Modular Construction

Artificial intelligence is no longer a future concept in modular construction—it is already reshaping how complex buildings are evaluated, designed, and delivered.

Gearing Up for the 2026 World of Modular

The Modular Building Institute (MBI) is bringing its global World of Modular (WOM) conference and tradeshow back to Las Vegas in April, and with it comes some of the industry’s best opportunities for networking, business development, and education.

New High-Rise Modular Apartment in Abu Dhabi Points Toward the Future of Multifamily Construction

Eagle Hills International Properties chose the BROAD Holon Building for a 16-story market rate apartment building in Zayed City, a central business district of Abu Dhabi. The project highlights the potential of the Holon system of volumetric modular construction to accelerate housing delivery.

MBI Announces First Ever Industry Apprenticeship Program in Collaboration with Marshall Advanced Manufacturing Center

MBI recently agreed to partner with Marshall Advanced Manufacturing Center (MAMC) to provide bona fide USDOL-approved apprenticeship programs for the industry.

MBI Leads the Charge for Passage of Amendment for New York’s Prevailing Wage Law, Protecting Modular Industry

MBI Leads the Charge for Passage of Amendment for New York’s Prevailing Wage Law, Protecting Modular Industry In December 2025, over MBI’s strenuous objections, New York Governor Kathy Hochul signed S.2536a, which expanded the state’s prevailing wage law to cover “off-site custom fabrication.” “Modules” were specifically cited for coverage under prevailing wage law. After close coordination between MBI, the bill’s sponsor, and Gov. Hochul’s office, the sponsor introduced A.9464, as a “clean-up…

MBI Hails Washington State House Passing ICC/MBI 1200 Standards Adoption Bill, Urges Senate To Follow

MBI Hails Washington State House Passing ICC/MBI 1200 Standards Adoption Bill, Urges Senate To Follow With housing a top issue for policymakers across the country, legislators in Washington are taking meaningful steps to increase the supply in the Evergreen State. First, we want to applaud the State House of Representatives for their unanimous passage of House Bill 2151, which will tackle one of…

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.