Barebottle Brewing Company

Company: UrbanBloc Inc.

Affiliates: R&S Tavares Associates

Location: San Francisco, CA, USA

Gross Size of Project: 320 Square Feet

Days to Complete: 285

Award Criteria

Architectural Excellence

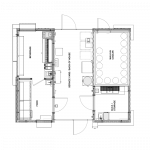

Barebottle is located in Salesforce Park on the top level of the 4-deck Transbay Tower in the heart of San Francisco. Two 20’ containers are placed back-to back. The front container has a bar with 20 taps and a small kitchen. The back container has a 13’ walk-in refrigerator and scullery. A glycol system runs from the walk-in to the taps. We included separate food service window on the side of the container to facilitate customer ordering and pickup. Between the containers is a 8’ inner utility courtyard with access through a handsome Garapa wood gate. Because the building is located in the center of Salesforce Park and is seen from all 360 degrees, the design had to be attractive from all sides including the roof. We used a combination of Garapa wood accents, signage, lighting, and stainless steel counters and drink rails to create a 360 degree customer experience. The building reflects the Barebottle branding with custom paint color, signage, and tiled backsplash.

Technical Innovation & Sustainability

The greatest technical challenge for this project was the inaccessible location. Barebottle is located in an existing park on the top floor of the transbay transit center in downtown San Francisco. The floor below is an active bus terminal. In order to address the unique challenges and cost of bringing utilities to the building through the 4 floors below, we created the inner courtyard to allow the utilities to be brought up from below to the top deck in a single, central location. The building itself had to be designed to accommodate a glycol system that ran from the walk-in cooler spanning the inner courtyard into the taps located in the front retail space. Security was also a concern so we used the existing container doors to secure the walk-in and a sliding barn door that doubles as a menu board to secure the tap room. The building meets all Title 24 energy requirements and is made with recycled shipping containers.

Cost Effectiveness

Due to the location of the site, there was a significant cost savings by using modular construction. Of the total $775K cost of the project, the building was only $281K. The buildings themselves were manufactured in 3 months and after the site was prepped, they were placed using a crane in less than 3 hours. The utility and electrical connections were straightforward, especially since the mechanical equipment was conveniently located in the inner courtyard between the containers. All plumbing connections were accessible from the side of the container enabling easy connections to the waste line. Through careful design and space usage, we were able to fit both the tap room and kitchen in one 20’ container further reducing the overall costs.

See More Awards of Distinction Winners

To view all our current honorees, visit our main Awards page.