Five Point Pop Up Park

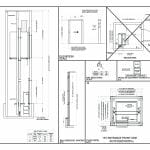

Company: Modular Elevator Manufacturing Inc.

Location: Irvine, California

Gross Size of Project: 2016 Square Feet

Days to Complete: 456

Award Criteria

Architectural Excellence

Architectural excellence is exhibited in the way the modular elevator was seamlessly integrated into an outdoors space in a pre-purposed storage container project with beauty and elegance. It incorporates a glass hoistway to give an open feel and less obstructed view of the surrounding 1500-acre park, soccer fields and dining area. A second-floor open walkway to the elevator is utilized making it separate from the overall structure. This important architectural detail gives a more open feel and free traffic flow. As a result of the architectural design the modular elevator was created and engineered to be a fully self-supporting structure in a high earthquake zone. In the Modern/Industrial style, the structure and awning were finished in the factory to be matte black, matching the surrounding railings and overall structure and theme. This project makes the outside a comfortable inside space.

Technical Innovation & Sustainability

The entire project is designed to be innovative and sustainable with use of used cargo containers creating an oasis in the vast park. The modular elevator is no exception. It is made of recyclable materials including a steel hoistway. All components are sized to reduce waste and increase efficiency. Also, organic hydraulic fluid is used in the conveyance system. It is safe for the environment even in the unlikely event an above ground jack leaks or fails. Another innovation is a detachable, recyclable awning system that can be easily replaced as needed. This extends the life span as an outside elevator, due to weather exposure, rarely last longer than the interior parts. Lastly, the MEM elevator reduced weeks of technicians coming and going from the jobsite while the hoistway and elevator components are being built or installed. This modular elevator installed in four hours and was ready for inspection in four days.

Cost Effectiveness

The cost of the MEM system for this build is comparable to any two-stop, glass hoistway elevator project. Under normal conditions there are some savings but are not represented in materials. The real savings are found in the specifications for this project. A free-standing steel and glass hoistway in the highest-level seismic zone were difficult for builders to cost out and drove estimates up. Our price did not change due to our experience and pre-approved engineering despite the challenges. Additional savings were provided by the reduction of man-hours compared to conventional construction. This project reduced total time onsite to four hours and in those four hours an entire installed elevator was placed. A conventional start up and installation is 4 to 16 weeks. Driving costs up more are the constant interruptions onsite delaying the project. The modular elevator is off the critical path reducing general construction costs as well. We easily won the competitive bid.

See More Awards of Distinction Winners

To view all our current honorees, visit our main Awards page.