Offsight’s Digital Certification Program Can Accelerate Modular Industry Growth

Vikas Murali is the CEO & Co-Founder at Offsight

When it comes to modular and offsite construction the benefits and advantages are widely known and accepted. Industry analysts have forecasted that the traditional construction value chain is ripe for disruption and a $256 Billion annual profit pool can be accessed by new offsite and modular businesses.

Analysis by McKinsey & Company already confirms that modular techniques accelerate construction timelines by 20 to 50 percent and can reduce overall costs by 20 percent. The benefits of modular construction over traditional methods are obvious and include faster project delivery, reduced overall project cost, and far greater overall project quality excellence. However, in the same analysis the authors directly address the key factors that must be addressed to accelerate modular adoption:

“The benefits of modular buildings come from the industrialization of key construction tasks. Modular companies aim to standardize, streamline, and automate big parts of the value chain, allowing buildings to be treated like products rather than projects. To get that right, modular players need best-in-class manufacturing capabilities, including sophisticated digital design platforms and lean, efficient production lines.”

In other words, simply moving work from a traditional job site into a factory doesn’t ensure that the true benefits of modular and offsite construction including speed, cost savings, and quality excellence are achieved. In order to truly realize the return on investment of offsite construction, companies must run a highly efficient manufacturing and production process. Investing in digitization and training your workforce to capitalize on the move to modular will be the key to truly harnessing the full potential and value add of offsite construction.

Going Digital, Getting Certified & Capturing The Full ROI of Modular Construction

At Offsight, we’ve built a solution specifically for the modular, offsite, and prefab industry. Our platform is robust enough to manage all forms of building project manufacturing over the full scope of prefab and modular product lines, from fully volumetric modules and bath pods to panels, trusses, and floor cassettes.

By developing a solution specific to the needs of the industry, we meticulously considered each aspect of managing a modular and prefab project at the factory level and built a full feature set to address the entire scope of factory operations. This includes Production & Quality Tracking, Reporting & Auditing, Advanced Analytics & Insights, Labor Tracking & Timesheets and Materials & Inventory Management.

To achieve the full potential from Offsight, our customers needed to drive adoption internally through educating their workforce and developing internal champions to learn our platform and train others. After witnessing our most successful modular customers deploy and expand our solution to their other factories successfully, Offsight was able to track progress and quality across several major commercial projects in parallel. We incorporated these insights into a digital certification and training program curated to foster shared knowledge among industry leaders within our customer base.

Related Listening:

The Value-Add of Offsite Construction Project Management Software w/ Offsight

Vikas Murali, CEO of Offsight, discusses the advantages that offsite factory owners and manufacturers can realize through the use of customized project management software. Vikas also talks about the development and capabilities of his company's Offsight software platform, as well as about how his background in enterprise-level software development—combined with the modular and offsite industry experience of his key staff—has led to Offsight's growth as an industry software solution.

To achieve the full potential from Offsight, our customers needed to drive adoption internally through educating their workforce and developing internal champions to learn our platform and train others. After witnessing our most successful modular customers deploy and expand our solution to their other factories successfully, Offsight was able to track progress and quality across several major commercial projects in parallel. We incorporated these insights into a digital certification and training program curated to foster shared knowledge among industry leaders within our customer base.

Commercial modular builder Z Modular utilizes Offsight to manage projects across multiple factories in the U.S. and Canada.

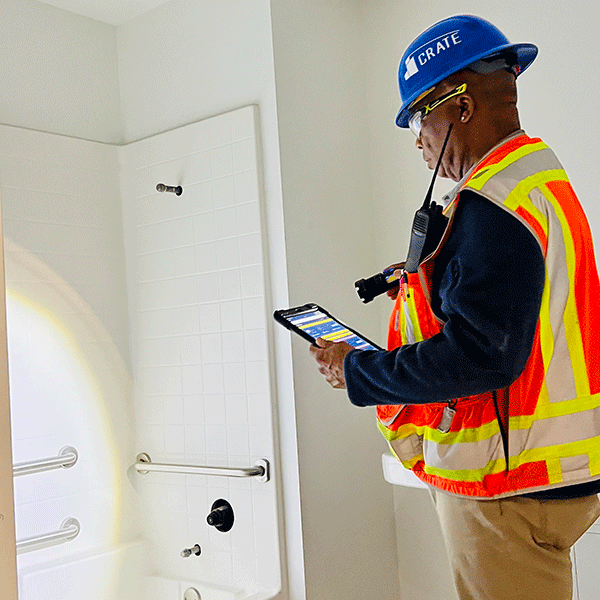

Multifamily residential builder CRATE Modular, leverages Offsight to manage full factory operations and production.

Therefore, we launched the Offsight Certification Program in January 2024. Our program is designed to equip production managers, quality inspectors, plant managers, and operators with a deeper understanding of how technology and digitization can be a game-changer in driving process improvements and productivity benefits, which will ultimately allow our customers to capture the full value of modular and offsite construction.

As Offsight Solutions Engineering Manager, Jason Dixon states: “Before joining Offsight, I held quality manager and operations roles at modular manufacturing companies. It was my responsibility to implement Offsight across our workforce of 50+ operators and managers. My biggest takeaway was the importance of training a technical lead responsible for learning how Offsight works and the value it can provide the factory. Our Offsight Certification Program will enable our clients to better train and recognize these internal leads and drive technological changes throughout the company.”

Our program consists of two major certifications that help operators, managers, and inspectors apply digitization to all aspects of factory operations. The Offsight Factory Operations Project Management Certification trains modular industry leaders in leveraging Offsight’s production, quality, analytics, and material and labor tracking capabilities to manage overall prefab project progress, collaborate with other project stakeholders, and accurately manage project costs. The Offsight Digital Quality Building Inspections Certification is designed to help quality personnel, managers and accredited building inspectors leverage digitization to manage complex code conformance and tracking, including mandatory and State-regulated reporting and auditing.

Through both programs, modular professionals learn how digitization can be a game-changer in driving modular construction adoption and delivering on the innate benefits the process offers.

As Offsight customer, Keizah Coye, Plant Project Manager at CRATE Modular, states: “As a production leader, I interact with Offsight daily. It’s a very robust solution that helps manage all factory operations and provides crucial visibility to our management. Their Certification and training program is exactly what production leaders in the modular, offsite, and prefab industry, like myself, need to quickly get up to speed on how Offsight’s technology can be utilized to meet our major operations and project goals and scale our business.”

At Offsight, our vision is to be the leading provider of digital tools and products that empower companies to unlock the complete potential of modular and offsite construction. We invite you to join us on this journey and hope that we can partner with you to help push the industry forward.

Specialty contractor PDM Constructors manages production across thousands of modular bath pods for major healthcare projects, through Offsight.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.