Modular Media Residence

As the biggest steelmaker in Korea, MBI member POSCO played a crucial part in helping PyeongChang, Korea prepare for the 2018 Olympic games. The company constructed, delivered, and, installed the International Broadcast Center (IBC), Media Residence Hotel and the Kwandong Hockey Center with its World Premium Products and innovative construction solutions.

solutions.

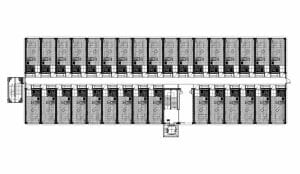

The media hotel is particularly noteworthy as 100 percent of the building was constructed off-site via modular construction. The 110,000 sf facility was constructed and opened in just 184 days! Compared to the time it would take to build a traditional concrete building of the same scope, the construction period for the Media Residence Hotel was 18 months shorter. Since each room is a relocatable building unit, it will be moved to a different venue and recycled as another hotel or dormitory.

The building consists of various units (room units, side exterior wall units, roof units, stair units and hall units). Modular room units (size 10.8ftx23ftx10.5ft) were designed with mobility and sustainability considerations. The unit exterior was designed to minimize the decorative elements and emphasize the aesthetic of natural material's characteristic to be functional. The lobby interior was designed as class and comfortable space with texture of steel itself and emotional design. Structure in ceiling of corridor was left exposed as an architecture design element. Performance and design were enhanced by adopting the unique texture of steel; high corrosion-proof steel instead of tile for high-grade unit bath system, fabric textured color-printed steel plate for system interior wall and clear color steel plate for the fire door. Free from potential nailing and taping scratches, artwork or photo frames can be posted on the wall magnetically.

According to the International Forum World Design Guide: “Most buildings created for the Winter Olympic Games have ultimately become “white elephants”. To avoid this problem, the PyeongChang Winter Olympics media residence was designed using relocatable building (RB) units as the media residence during the Games. Afterwards, the buildings were dismantled, and the site was restored to its original condition. Best of all, the RB units will be relocated and reused. To achieve this, the building design followed a fourfold concept: relocatable; reusable; recyclable (steel-based design); and reduced (100% factory made).

This article was adapted from an Awards of Distinction entry. Browse more projects.

More from Modular Advantage

AI, Faster Sets, and Automation: The Future of Modular is at World of Modular

While the modular building industry has long known that it can be an effective solution to increase affordable housing, the word is slowly spreading to more mainstream audiences. Three presentations at this year’s World of Modular in Las Vegas hope to provide insight and direction for those seeking a real solution to the crisis.

An Insider’s Guide to the 2025 World of Modular

The Modular Building Institute is bringing its global World of Modular (WOM) event back to Las Vegas, and with it comes some of the industry’s best opportunities for networking, business development, and education. Over the course of the conference’s four days, there will be numerous opportunities for attendees to connect, learn, and leverage event resources to get the most out of the conference.

Affordable Housing Now: The Industry’s Best Bring New Solutions to World of Modular

While the modular building industry has long known that it can be an effective solution to increase affordable housing, the word is slowly spreading to more mainstream audiences. Three presentations at this year’s World of Modular in Las Vegas hope to provide insight and direction for those seeking a real solution to the crisis.

Opportunities for Innovation in Modular Offsite Construction

Modular Offsite Construction has already shattered the myth that it only produces uninspired, box-like designs. Architectural innovations in module geometry, configurations, materials, and products make it possible to create visually stunning buildings without sacrificing functionality or efficiency.

Safe Modular Construction with Aerofilm Air Caster Transport

In collaboration with Aerofilm Systems, Heijmans developed innovative skids using air caster technology for moving modules easily and safely. These pallets are equipped with an auto-flow system, making operation extremely simple.

Miles, Modules, and Memes: Building a Modular Network One Flight at a Time

At the end of the day, social media is just another tool for building connections, and like any other tool, needs to be used skillfully to work properly. Use social media thoughtfully, and it will open doors to real opportunities and relationships you didn’t even see coming.

Falcon Structures: Thinking Inside the Box

Some of Falcon’s latest projects include creating container solutions for New York’s Central Park and an East Coast professional baseball team. More and more, Falcon is shipping out container bathrooms and locker rooms to improve traditionally difficult work environments, like those in oil and gas or construction.

UrbanBloc—From Passion to Industry Leader

UrbanBloc specializes in three main categories or markets – what they call “Phase 0” projects, amenities, and urban infill. Clients are often attracted to shipping containers because from a real estate perspective they are considered an asset. Having the flexibility to move and transport these assets allows owners to respond to different circumstances in a fluid manner that they can’t get with standard construction.

The Hospitality Game-Changer

“Hospitality is about more than just providing a service – it’s about delivering an experience,” says Anthony Halsch, CEO of ROXBOX. “And that’s where containers thrive. They allow us to create spaces that are unique, efficient, and sustainable.”

Container Conversions Counts on Simplicity to Provide Critical Solutions

Container Conversions has fabricated and developed thousands of containers for varied projects, including rental refrigeration options, offices, kitchens, temporary workplace housing, and mobile health clinics.