DORCE Designs and Exports Volumetric Modular Buildings to 6 Continents

DORCE offers “Convertible and eco-friendly” volumetric modular steel structures

Today we witness “convertible and eco-friendly” volumetric modular buildings stand out in industrialized construction with new construction technologies, new construction methods, and innovative materials, unlike those used in traditional building systems.

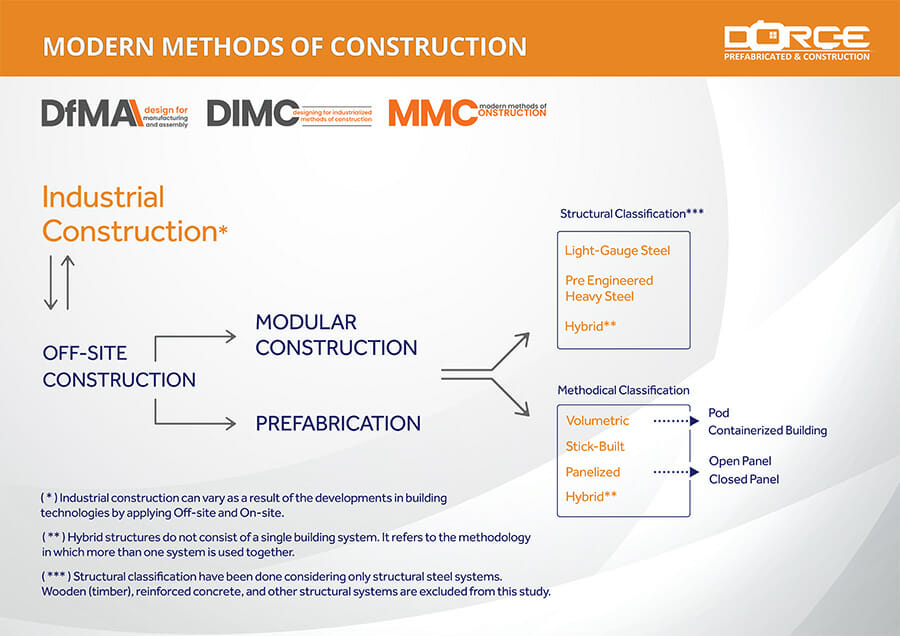

Prefabricated modular building elements offer high-quality projects with lower costs and optimized & accelerated construction programs. The concepts such as Design for Manufacturing and Assembly (DfMA) & Designing for Industrialized Methods of Construction (DIMC) constitute the most basic and modern elements of Off-site construction and Modern Methods of Construction (MMC).

Demand has been increasing in sectors such as education, entertainment, health services, and housing

Mobile life offers fast and practical solutions with prefabricated modular structures to all the sudden and changing needs of people far away from their homes in the most severe climatic conditions. Stable architectural solutions used in built-in building systems have

begun to be replaced seriously by modular building systems. Demand for modular building systems has been increasing day by day in many areas of our lives such as education, entertainment, health services, and housing.

In general, modular building systems can be classified as permanent and mobile modular buildings.

Permanent modular buildings

Permanent modular buildings include schools, hospitals, shopping malls, clinics, residences, housing units, vehicle inspection stations, police stations, warehouses, hangars, administrative buildings, office buildings, hotels, and dormitories.

Mobile modular buildings

Mobile modular buildings include caravans, trailers, tiny houses, modular containers, temporary emergency & disaster facilities, integrated refugee facilities / camps, worker accommodation camps, labour quarters, and mobile hospitals.

Volumetric modular buildings of DORCE can be used as a traditional accommodation as well as temporary – volumetric modular accommodation in disaster and war zones; they are also used as temporary residential camps or permanent accommodation facilities at construction sites, oil & gas, mining, drilling, offshore and pipeline sites.

Related Reading:

Advantages of Digital Prefabrication for the Modern Construction Industry

DORCE Prefabricated Building & Construction Industry Trade Inc. manufactures prefabricated modular building components directly with Building Information Modeling (BIM) and completes their assemblies completely digitally off-site.

This article details all the benefits realized through digital prefabrication and shows how other manufacturers can capitalize on this popular method of project deisgn.

Modular units manufactured in a controlled environment

Modular building systems, manufactured by DORCE, are used for projects that require rapid solutions and must be completed in harsh climatic and geographical conditions. The component of modular buildings manufactured in a controlled environment at the industrialized facility (factory conditions) and transported to the construction site as units and assembled at the place.

DORCE completes staff accommodation facilities in Kazakhstan with volumetric modular building system

Last year, DORCE has successfully completed construction of Copper Mine Staff Accommodation Facilities within the scope of the Aktogay Expansion Project in Kazakhstan.

Pre-manufactured containerized modular units are manufactured at the Dorce production plant in Turkey, delivered as flat-packed and each module is assembled at Dorce workshops in Kazakhstan. Thereafter, modules delivered to the site in Aktogay and erected side by side and stacked to create a complete structure.

The connection of all modular buildings is done at the construction site. They are immediately made weathertight to protect the interior and interconnected structurally. The finishes and mechanical connections are completed, and all systems are inspected and tested. Custom features such as site applied finishes, pitched roofs and other architectural treatments can be added to make the building a customized structure, ideally suited for its specific use.

10 modular buildings with 1,628 modules in total

Finally, the entire structure composes of 10 modular buildings consisting of 1,628 modules in total.

Building modules are demountable, transportable, and designed to allow an easy dismantling and erection for several times. Volumetric modular buildings of DORCE are designed to be assembled on the reinforced concrete columns with anchorages above the ground level.

Off-site construction at -40 degrees climate conditions

These types of building systems allow the rapid formation of larger interior volumes and larger structures by coming together of modules as volumetric structures. Copper Mine Accommodation Facilities Project of DORCE in Kazakhstan – Aktogay was completed with “volumetric” building systems in -40 degrees climate conditions.

Volumetric modular building systems offer plenty of advantages

The advantage of this method is that all conditions are under control since the manufacturing process takes place in the factory environment. Thus, the quality of the produced materials increases. Fire, sound, and thermal insulation can be made as desired and accordingly with the requirements of projects and customers. In addition, this Modern Method of Construction (MMC) saves time.

Volumetric modular construction provides many advantages to people as a part of today’s modern living spaces and offer practical solutions in accordance with the changing needs of people. Volumetric modular buildings are permanent or temporary structures that can be equipped with high-level technology, meet their own needs, even solve their sub-structural needs such as energy recovery and waste recycling. They are lightweight, easily assembled and disassembled and transportable from one location to another.

More from Modular Advantage

AI, Faster Sets, and Automation: The Future of Modular is at World of Modular

While the modular building industry has long known that it can be an effective solution to increase affordable housing, the word is slowly spreading to more mainstream audiences. Three presentations at this year’s World of Modular in Las Vegas hope to provide insight and direction for those seeking a real solution to the crisis.

An Insider’s Guide to the 2025 World of Modular

The Modular Building Institute is bringing its global World of Modular (WOM) event back to Las Vegas, and with it comes some of the industry’s best opportunities for networking, business development, and education. Over the course of the conference’s four days, there will be numerous opportunities for attendees to connect, learn, and leverage event resources to get the most out of the conference.

Affordable Housing Now: The Industry’s Best Bring New Solutions to World of Modular

While the modular building industry has long known that it can be an effective solution to increase affordable housing, the word is slowly spreading to more mainstream audiences. Three presentations at this year’s World of Modular in Las Vegas hope to provide insight and direction for those seeking a real solution to the crisis.

Opportunities for Innovation in Modular Offsite Construction

Modular Offsite Construction has already shattered the myth that it only produces uninspired, box-like designs. Architectural innovations in module geometry, configurations, materials, and products make it possible to create visually stunning buildings without sacrificing functionality or efficiency.

Safe Modular Construction with Aerofilm Air Caster Transport

In collaboration with Aerofilm Systems, Heijmans developed innovative skids using air caster technology for moving modules easily and safely. These pallets are equipped with an auto-flow system, making operation extremely simple.

Miles, Modules, and Memes: Building a Modular Network One Flight at a Time

At the end of the day, social media is just another tool for building connections, and like any other tool, needs to be used skillfully to work properly. Use social media thoughtfully, and it will open doors to real opportunities and relationships you didn’t even see coming.

Falcon Structures: Thinking Inside the Box

Some of Falcon’s latest projects include creating container solutions for New York’s Central Park and an East Coast professional baseball team. More and more, Falcon is shipping out container bathrooms and locker rooms to improve traditionally difficult work environments, like those in oil and gas or construction.

UrbanBloc—From Passion to Industry Leader

UrbanBloc specializes in three main categories or markets – what they call “Phase 0” projects, amenities, and urban infill. Clients are often attracted to shipping containers because from a real estate perspective they are considered an asset. Having the flexibility to move and transport these assets allows owners to respond to different circumstances in a fluid manner that they can’t get with standard construction.

The Hospitality Game-Changer

“Hospitality is about more than just providing a service – it’s about delivering an experience,” says Anthony Halsch, CEO of ROXBOX. “And that’s where containers thrive. They allow us to create spaces that are unique, efficient, and sustainable.”

Container Conversions Counts on Simplicity to Provide Critical Solutions

Container Conversions has fabricated and developed thousands of containers for varied projects, including rental refrigeration options, offices, kitchens, temporary workplace housing, and mobile health clinics.