Modular Multi-family Construction: A Field Study of Energy Code Compliance and Performance through Offsite Prefabrication

Kevin Grosskopf is a professor at the University of Nebraska-Lincoln

Prefabrication in a factory setting may improve the performance of modular buildings compared to traditional site-built buildings. To validate this premise, the U.S. Department of Energy (DOE) funded a 3-year study from 2020-2023 comparing the energy performance of more than 50 modular and site-built multifamily buildings under construction in Los Angeles, San Francisco, Philadelphia and Seattle. In addition to energy performance, DOE was also interested in the potential cost savings of modular construction as well as other market opportunities and challenges.

Crane set at a modular jobsite (VBC), Philadelphia PA, 2022. 260,000 sq. ft. mixed-use project consisting of 5-stories and 410 residential modular units over 2-stories of site-built commercial podium.

Part I - Energy Performance

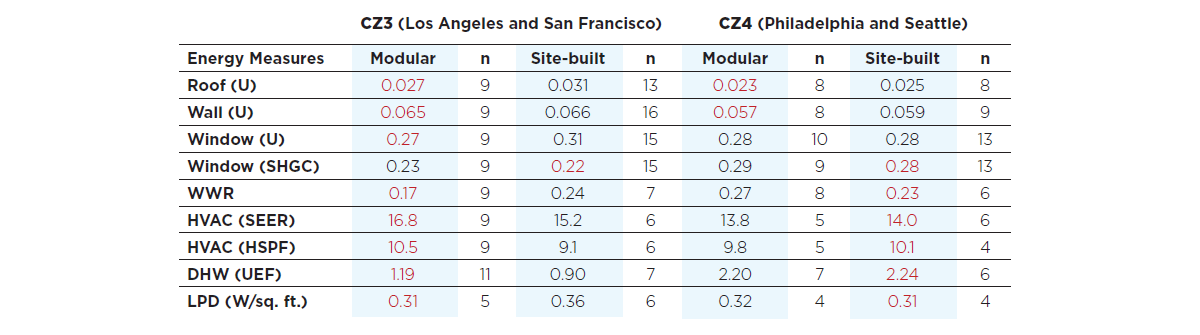

Multifamily buildings selected for this study averaged 6 stories, 140,390 sq. ft. square-feet and 144 units. Data was collected on several energy-related material and equipment systems. Data collection for each project began with a plan review followed by two field inspections. For modular projects, the first inspection was conducted at the factory and a second inspection was conducted at the construction site. Findings indicate that the performance of key energy-related materials and equipment in modular multifamily construction was somewhat better than those found in site-built, particularly in climate zones 3 (Los Angeles and San Francisco).

The DOE study also looked at the post-occupancy energy performance of another 20 modular multifamily buildings completed between 2013-2022 in these same areas. While there appeared to be little difference between the annual energy use in modular multifamily buildings (36.0 kBtu/sq. ft./yr) compared to more than 120 site-built buildings (35.8 kBtu/sq. ft./yr), ENERGY STAR™ scores for modular (86) were higher on average compared to site-built (81).

Given that most of the modular buildings in this study were affordable housing, apartment units were smaller on average (560 sq. ft.) compared to site-built units (830 sq. ft.). As a result, occupant density in modular multifamily buildings was 30-50% higher. When normalized for this, the energy performance of modular multifamily construction is likely (much) better than site-built. Although few differences were observed between the types of materials and equipment used in either modular or site-built multifamily construction, installation quality appeared to be significantly better in modular.

Part II - Market Opportunities & Challenges

During factory and construction site inspections, interviews were conducted with project stakeholders to identify key market implementation opportunities and challenges. Findings suggest that the most significant advantage of modular construction is schedule savings. Offsite prefabrication can proceed simultaneously with onsite construction, reducing time, project overhead and the impact of weather. Overall, modular buildings in this study were completed 25-30% faster on average when compared to site-built buildings. Despite added transportation costs, modular construction ($243/sq. ft.) was also found to be cost-competitive with site-built construction ($251/sq. ft.), particularly when considering shortened construction schedules and speed to market.

Yet, persistent barriers to modular market growth remain, including a building industry that is unwilling to change from traditional site-built methods, consideration of modular too late in the design process, lack of modular industry standards, and the risks associated with modular builders as a very large suppliers or subcontractors in the design-bid-build delivery process.

To address these issues, some manufacturers have undertaken a greater role in the design-manufacture-construct process. Specifically, manufacturers have begun to offer ‘turn-key’ building solutions by providing design, manufacturing and construction services in-house. By doing so, a commitment to modular is made at the beginning of the project, saving time and money. The inefficient, even adversarial relationship between designers, manufacturers, and site contractors is replaced with a single, fixed-price contract between developer and manufacturer before production begins. Profits are tied to overall project performance, not to the performance of individual players in the traditional design-bid-build process.

Production line at a modular factory (Nashua Builders), Nampa ID, 2023.

Conclusion

With greater control over the project design, as well as the number and timing of projects undertaken, modular manufacturers in the design-manufacture-construct process can better achieve product standardization within their factories and sustain production between project cycles. In doing so, factories can be operated more efficiently with less worker turnover.

Download the Complete Report

Download a complete copy of Kevin Grosskopf's 2023 report "Modular Multi-family Construction: A Field Study of Energy Code Compliance and Performance through Offsite Prefabrication"

More from Modular Advantage

An Insider’s Guide to the 2025 World of Modular

The Modular Building Institute is bringing its global World of Modular (WOM) event back to Las Vegas, and with it comes some of the industry’s best opportunities for networking, business development, and education. Over the course of the conference’s four days, there will be numerous opportunities for attendees to connect, learn, and leverage event resources to get the most out of the conference.

Affordable Housing Now: The Industry’s Best Bring New Solutions to World of Modular

While the modular building industry has long known that it can be an effective solution to increase affordable housing, the word is slowly spreading to more mainstream audiences. Three presentations at this year’s World of Modular in Las Vegas hope to provide insight and direction for those seeking a real solution to the crisis.

Opportunities for Innovation in Modular Offsite Construction

Modular Offsite Construction has already shattered the myth that it only produces uninspired, box-like designs. Architectural innovations in module geometry, configurations, materials, and products make it possible to create visually stunning buildings without sacrificing functionality or efficiency.

Safe Modular Construction with Aerofilm Air Caster Transport

In collaboration with Aerofilm Systems, Heijmans developed innovative skids using air caster technology for moving modules easily and safely. These pallets are equipped with an auto-flow system, making operation extremely simple.

Miles, Modules, and Memes: Building a Modular Network One Flight at a Time

At the end of the day, social media is just another tool for building connections, and like any other tool, needs to be used skillfully to work properly. Use social media thoughtfully, and it will open doors to real opportunities and relationships you didn’t even see coming.

Falcon Structures: Thinking Inside the Box

Some of Falcon’s latest projects include creating container solutions for New York’s Central Park and an East Coast professional baseball team. More and more, Falcon is shipping out container bathrooms and locker rooms to improve traditionally difficult work environments, like those in oil and gas or construction.

UrbanBloc—From Passion to Industry Leader

UrbanBloc specializes in three main categories or markets – what they call “Phase 0” projects, amenities, and urban infill. Clients are often attracted to shipping containers because from a real estate perspective they are considered an asset. Having the flexibility to move and transport these assets allows owners to respond to different circumstances in a fluid manner that they can’t get with standard construction.

The Hospitality Game-Changer

“Hospitality is about more than just providing a service – it’s about delivering an experience,” says Anthony Halsch, CEO of ROXBOX. “And that’s where containers thrive. They allow us to create spaces that are unique, efficient, and sustainable.”

Container Conversions Counts on Simplicity to Provide Critical Solutions

Container Conversions has fabricated and developed thousands of containers for varied projects, including rental refrigeration options, offices, kitchens, temporary workplace housing, and mobile health clinics.

Revelution Containers and S. I. Container Builds: On a Mission to Revelutionize Housing

Rory Rubun and Pam Bardhi are on a mission to create more housing. Together, they plan to build shipping container eco communities similar to single-family subdivisions, and mixed-use buildings in urban settings. They also want to expand the footprint of ADUs across the nation.