UNB OCRC Student Off-Site Design Competition Crowns 2023 Winners

For the third year in a row, the University of New Brunswick’s Off-Site Construction Research Centre (OCRC), a research group dedicated to optimizing alternate solutions to on-site construction, presented its Off-site Construction Student Design Competition. This competition—presented again by the Modular Building Institute (MBI)—showcased student design innovation in modular, prefabricated, panelized, and other types of off-site construction and featured entries from dozens of interdisciplinary collegiate teams across Canada.

The objective of the competition was simple: to introduce students to offsite construction and to encourage interdisciplinary collaboration. It was also an opportunity to showcase how offsite construction’s many benefits, including reduced construction timelines, improved safety, and improved construction quality, can benefit the construction industry.

The Challenge

For this most recent competition, teams were tasked with developing a modular design for a housing unit that will be ‘open source’ and be used by manufacturers to meet the demand for affordable housing in New Brunswick. The design needed to focus on a repeatable volumetric module that could be used to combat the “missing middle housing” problem.

The Winners

First Place: Transition

Team members: Kateryna Stokoz, Luke De Bartolo, Stefan Giro (Toronto Metropolitan University)

The first-place prize in 2023 went to Transition, a project from a three-student team from Toronto Metropolitan University. The team’s idea aims to revolutionize the concept of transitional housing for youth leaving the child welfare system. It goes beyond traditional social housing models, offering young individuals a nurturing space to grow and thrive.

“Our approach started with a thorough understanding of New Brunswick's specific needs for affordable housing – aiming for a tailored solution that also aligned with the principles of open-source development,” said team member Kateryna Stokoz. “When we learned about young adults' struggles leaving the child welfare system, it became clear that our focus should be on designing affordable housing specifically for this demographic.”

“We approached the design process in two parts: the individual units and the building complex,” continued team member Luke De Bartolo. “From the beginning, our vision for the building complex revolved around fostering a diverse community where different groups could coexist and mutually benefit from each other. We're talking about families next to older folks, doctors living near patients, and teachers among their students. Imagine a young adult who grew up in the foster system living among successful adults in this modular community. It's a setup where they can feel more included and have role models to look up to. For us, it was about creating a community where everyone benefits.”

“Participating in this competition was a great learning experience for our team,” said team member Stefan Giro. “It helped us gain a deeper understanding of modular housing. While developing our design, we discovered various logistical challenges and opportunities for creative problem-solving, from the initial stages to the on-site construction of modules.

“One significant lesson we've taken away is the crucial role of off-site modular construction in addressing housing shortages,” concluded Giro. “Our focus on New Brunswick highlighted the potential for adaptability of modular housing to be used in other areas facing housing needs more efficiently than traditional construction methods.”

Second Place: Simplex

Team members: Til Schmitt-Ulms, Aryan Star, Gashtiyar Fathullah (University of New Brunswick)

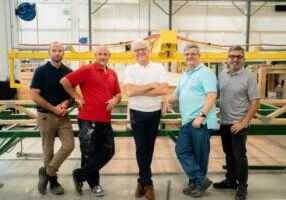

With perhaps the most professional experience of the participating teams, this three-student group brought diverse experiences to the table. Gashtiyar Fathullah and Aryan Star, both recent graduates of the University of New Brunswick and now involved in Kent Homes, have direct experience in modular construction and automation. Til Schmitt-Ulms, a civil engineering student at University of British Colombia, contributed a fresh academic perspective and hands-on experience from Stack Modular.

“The focus for this project,” said team member Til Schmitt-Ulms, “was on reducing transportation costs and enabling modular manufacturers to access a larger market by developing standardized modules (wet modules with MEPs and normal modules) with shipping container sizes so that they can be transported by trucks, trains, and ships.”

“We believe affordability comes by creating more units on a smaller piece of land rather than independent unit on each plot of land,” continued team member Aryan Star. “We tried to design a multiplex with 12 apartments to show our beliefs, each apartment has one wet modules for kitchen and bathroom with multiple bedrooms and in suit laundry with access to two private balconies acting as terrace on the roof of your neighbor downstairs.”

“I think the future of housing lies in modular construction,” concluded team member Gashiyar Fathullah, “especially in cold climates which makes business sense because of the lack of workers. I see a future where you can order your house on your mobile and it updates you on how it’s going, just like a car.”

Presenting the Industry's Future

MBI is proud of its continued sponsorship of the University of New Brunswick's Off-Site Construction Research Centre's annual Off-site Construction Student Design Competition. Besides the opportunity to share exciting new ideas about how to implement modular and offsite construction to address current needs, the contest is chance to showcase the industry's rapidly growing pool of young talent.

"We look forward to this contest every year," said John McMullen, PCM, marketing director at MBI. "It's great to work with UNB to showcase these projects, and we love the opportunity to support students and young professionals interested in modular construction. It's a huge win-win."

Congratulations again to all of 2023 Competition entrants!

About the Author: John McMullen, PCM, is the marketing director for the Modular Building Institute. You can reach him directly at mcmullen@modular.org or on LinkedIn.

More from Modular Advantage

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.

ModMax: Redefining Modular Construction with Confidence and Precision

ModMax was born out of frustration—frustration with five persistent pain points in modular construction: Permitting bottlenecks. Production delays. Rigid designs. Disconnect between “the office” and the field. Lack of transparency and communication.

LifeArk: Disaster-Resilient Housing from Recycled Plastic and 100-year-old Technology

Wee compares LifeArk’s housing units to Yeti coolers, as they are built similarly. Each component takes 15 to 20 minutes to manufacture, has an R-value of 40, and includes molded slots and chases for wiring, plumbing, fire sprinklers, and other utilities.

Building the Future of Modular Edge Infrastructure

The edge data center market is expanding rapidly, driven by the surge in AI workloads, IoT adoption, and the need for localized compute power. In these environments, sustainability, scalability, and reliability are non-negotiable. Cooling is among the most complex challenges for operators—and one of the most decisive factors in long-term success.

Accelerating Light-Gauge Steel Construction: A Semi-Automated Digital Workflow for Off-Site Projects

For construction professionals, the message is clear. By adopting semi-automation and digitalization, companies can deliver projects faster, more accurately, and more profitably, while also building stronger collaboration across teams. The approach is not about replacing people with machines, but about empowering people with better tools and processes.

Why Modular Data Centers Are Gaining Momentum

Artificial intelligence, high-performance computing, and edge applications push the limits of traditional “stick-built” data centers. They take years build, often struggle with high density workloads, and aren’t optimized for deployments near end users. Modular data center platforms are purpose-built to address these challenges, offering flexibility and scalability to adapt to evolving technologies, while opening new opportunities for the modular construction industry.

Supply Chain Innovation in Action: 5 Habits Every Modular Leader Should Practice

By applying these principles to supply chain practices — collaborative planning, strategic procurement, scenario modeling, digital tools, and transparent forecasting — construction leaders can build value chains that are not just efficient and agile, but truly innovative.

Exploring the Role of Modular Integrated Construction (MiC) in Advancing Circular City Principles – A Survey of Stakeholder Perspectives

The survey findings highlight the significant potential of Modular integrated Construction (MiC) in advancing the development of circular cities. By reducing costs, accelerating construction timelines, and minimizing waste generation, MiC offers a promising approach to sustainable urban development.

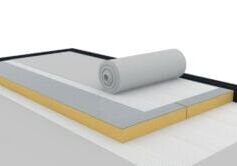

The Use of MS POLYMER™-Based Sealants and Adhesives in Modular Building

These products combine flexibility and elastic recovery with excellent adhesion to different substrates and have already shown their usefulness in traditional construction. Now it’s time for them to be put to use in the modular construction industry.