Newest Line of Container Buildings Broadens Modular’s Reach

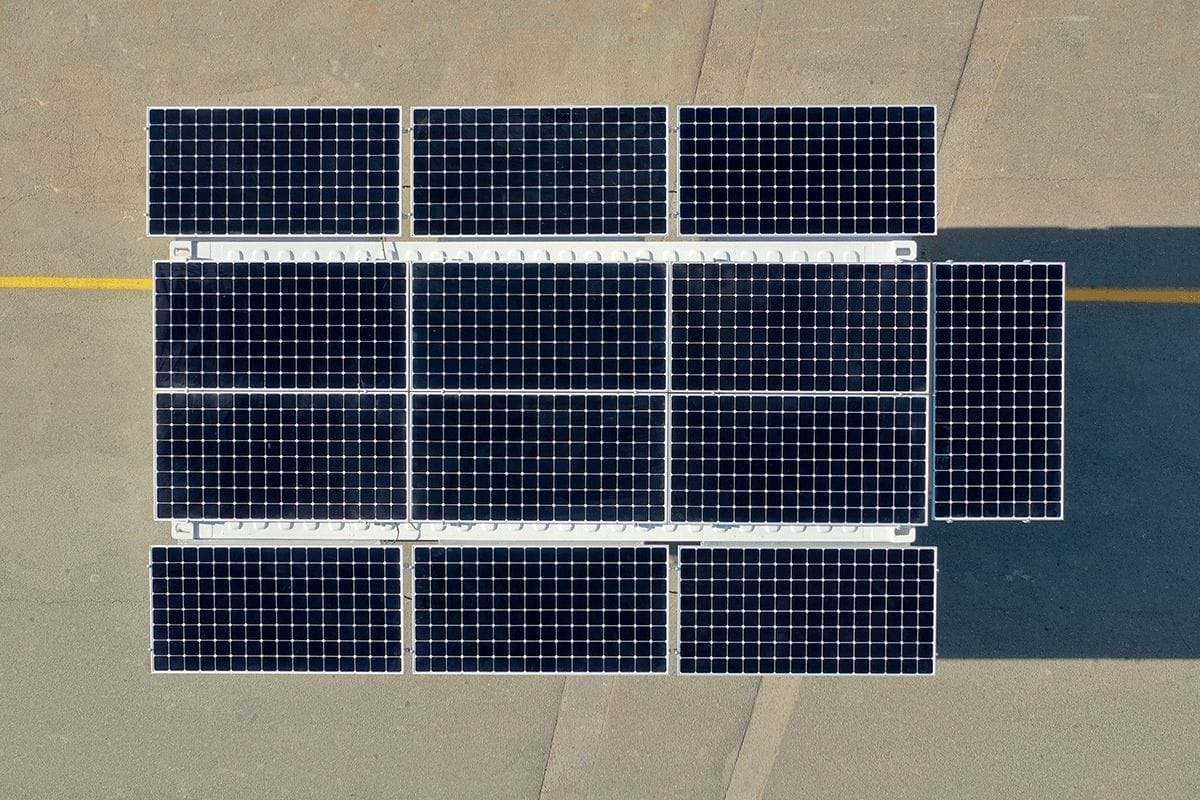

Wilmot Modular’s newest line of mobile storage and office buildings is set to expand the reach of modular buildings into remote locations. Their Smart Line – Hybrid Series of container offices and storage buildings provides almost instant connectivity and power in locations that are off-grid, on-grid, or anywhere in between. With a robust solar power generation and storage system, they can be placed nearly anywhere there is access to sunlight and can provide enough power to remain self-sufficient.

Wilmot partnered with Prospect Solar, bringing their modular expertise and combining it with the latest in solar power generation and storage technologies to create a new line of solar powered container offices and storage buildings. Early interactions between the two revealed a strong alignment between their core values, paving the way for a fruitful collaboration.

The Smart Line models come in two sizes: 20 feet and 40 feet. The 20-foot model comes with 13 solar panels that generate 410 watts each, for a total of approximately 5.33 kW. It comes with an 18.4 kWh lithium phosphate battery. The 40-foot model comes with 25

panels at 410 watts each, for a total of approximately 10.25 kW. Depending on how many batteries are installed, it can store 36.8 to

73.6 kWh. Excess power generated by the solar arrays can be used to recharge the batteries, supply power to other modular units, or

potentially can be fed back into the grid, subject to local regulations and grid capabilities.

The basis for the Smart Line design was driven by Wilmot’s commitment to environmental responsibility and their ambition to provide innovative solutions within the industry. They began by recognizing the need for efficient, sustainable, and rapidly deployable solar powered office and storage solutions, especially in remote locations. Through the design process, they were able to successfully integrate solar power into shipping containers, and created a product that can be operational within minutes of being deployed. This feature can be particularly valuable in remote areas, where setting up grid connections can be time-consuming, often taking weeks or months.

Shipping containers were chosen as the foundational structures for these specialty units because of their structural integrity, modularity, sustainability, and cost effectiveness. The initial Smart Line – Hybrid Series (version 1) effectively powered the HVAC and lighting systems, but it faced certain operational challenges. Specifically, the side panels or “wings” – essential for increasing solar panel area – had to be retracted in winds exceeding 35 mph, and they were deployed manually, which was cumbersome.

In response, version 2 was developed with significant design enhancements. The improved wing design now withstands higher wind conditions, up to 115 mph, without the need for retraction. Additionally, an automated electronic system for wing deployment was developed. This innovation simplifies the deployment process, minimizes labor efforts, and enhances safety. Overall, these developments have substantially boosted the operational efficiency and strength of the units.

There are several advantages to using Smart Line units. They offer substantial energy generation capabilities, enough to power key functions (HVAC and lighting), especially in the larger 40’ unit with its increased panel count and battery capacity. By significantly reducing or even eliminating reliance on external power sources, customers can also achieve notable savings in energy costs. Additionally, the units offer multiple power options, including solar, battery, optional generator, and a grid power inlet. This versatility and flexibility help ensure consistent power even in remote or unstable grid situations. The units can help customers meet their environmental and sustainability targets through qualification for incentives or tax credits. (Wilmot will be pursuing LEED certification for the units in the near future.) Finally, investing in solar-powered units now can be offset by long-term energy savings and potential financial incentives.

Wilmot is a long-standing family-run business that has always lead by being at the forefront of modular and container buildings technology. Chris Wilmot, Marketing Director, and Kevin Wilmot, Sales Director, have both learned the business from the ground up, starting by working in the field. They’ve watched the steady growth of the company started by their parents, Mike and Kathy Wilmot. Chris began his career after high school when he worked in fleet maintenance. He worked his way up to Manager while earning his marketing degree. He was promoted to Marketing Director in 2022. Kevin also started his career in fleet maintenance after high school. He then moved to field installations, until transferring to sales about ten years ago.

Both say they have learned a lot experiencing the industry from the ground up. Backed by decades of watching the ebb and flow of the industry, they are poised to continue innovating to keep their market edge. Chris said, “Witnessing the growth of our family business from a simple trailer to a major regional player has been a journey of inspiration, rooted in our parents’ dedication and hard work.” “We’ve both seen what happens when the economy has a downturn and fleet units start flooding back into the yard,” said Kevin. “We’ve also seen the good times when we run out of fleet because of high demand. Our parents have allowed us to grow in the business and have always explained the reason for different decisions so we can understand how to run a business. Our shared legacy, founded on the solid groundwork laid by our parents, motivates us to continue pushing the boundaries in the modular construction industry.”

The company provides a range of modular options, from state-of-the-art modular buildings and versatile mobile offices to practical office containers and storage solutions, like plant mezzanines. Their goal is always to cater to the diverse needs of their customers with excellence and efficiency.

The primary objective of this new partnership with Prospect Solar is to revolutionize the perception and functionality of typical mobile offices and storage spaces. Together they are focused on offering solutions that are not only sustainable, but also convenient and cost effective. The line is targeted to those who prioritize sustainability and eco-friendliness without compromising efficiency and cost effectiveness. This includes businesses and individuals seeking practical, portable solutions that are both environmentally responsible and adaptable to a variety of uses.

Wilmot hopes to continue its innovation into 2024. They are looking forward to a suite of offerings that will not only emphasize customization but also set new industry standards in efficiency and eco-responsibility, solidifying their standing as leaders in the modular building industry.

About the Author: Dawn Killough is a freelance construction writer with over 25 years of experience working with construction companies, subcontractors and general contractors. Her published work can be found at dkilloughwriter.com.

More from Modular Advantage

AI, Faster Sets, and Automation: The Future of Modular is at World of Modular

While the modular building industry has long known that it can be an effective solution to increase affordable housing, the word is slowly spreading to more mainstream audiences. Three presentations at this year’s World of Modular in Las Vegas hope to provide insight and direction for those seeking a real solution to the crisis.

An Insider’s Guide to the 2025 World of Modular

The Modular Building Institute is bringing its global World of Modular (WOM) event back to Las Vegas, and with it comes some of the industry’s best opportunities for networking, business development, and education. Over the course of the conference’s four days, there will be numerous opportunities for attendees to connect, learn, and leverage event resources to get the most out of the conference.

Affordable Housing Now: The Industry’s Best Bring New Solutions to World of Modular

While the modular building industry has long known that it can be an effective solution to increase affordable housing, the word is slowly spreading to more mainstream audiences. Three presentations at this year’s World of Modular in Las Vegas hope to provide insight and direction for those seeking a real solution to the crisis.

Opportunities for Innovation in Modular Offsite Construction

Modular Offsite Construction has already shattered the myth that it only produces uninspired, box-like designs. Architectural innovations in module geometry, configurations, materials, and products make it possible to create visually stunning buildings without sacrificing functionality or efficiency.

Safe Modular Construction with Aerofilm Air Caster Transport

In collaboration with Aerofilm Systems, Heijmans developed innovative skids using air caster technology for moving modules easily and safely. These pallets are equipped with an auto-flow system, making operation extremely simple.

Miles, Modules, and Memes: Building a Modular Network One Flight at a Time

At the end of the day, social media is just another tool for building connections, and like any other tool, needs to be used skillfully to work properly. Use social media thoughtfully, and it will open doors to real opportunities and relationships you didn’t even see coming.

Falcon Structures: Thinking Inside the Box

Some of Falcon’s latest projects include creating container solutions for New York’s Central Park and an East Coast professional baseball team. More and more, Falcon is shipping out container bathrooms and locker rooms to improve traditionally difficult work environments, like those in oil and gas or construction.

UrbanBloc—From Passion to Industry Leader

UrbanBloc specializes in three main categories or markets – what they call “Phase 0” projects, amenities, and urban infill. Clients are often attracted to shipping containers because from a real estate perspective they are considered an asset. Having the flexibility to move and transport these assets allows owners to respond to different circumstances in a fluid manner that they can’t get with standard construction.

The Hospitality Game-Changer

“Hospitality is about more than just providing a service – it’s about delivering an experience,” says Anthony Halsch, CEO of ROXBOX. “And that’s where containers thrive. They allow us to create spaces that are unique, efficient, and sustainable.”

Container Conversions Counts on Simplicity to Provide Critical Solutions

Container Conversions has fabricated and developed thousands of containers for varied projects, including rental refrigeration options, offices, kitchens, temporary workplace housing, and mobile health clinics.