Enthusiasm for Modular Construction Grows in Ukraine as Rebuilding Efforts Take Shape

The future of Ukraine may be uncertain, but one thing isn’t: rebuilding will be a monumental task.

Bruce Talley, Chief Operating Officer at MBI member company OFC Incorporated, is trying ensure that Ukraine’s eventual rebuilding efforts are based in a technology known for its speed and adaptability: modular construction.

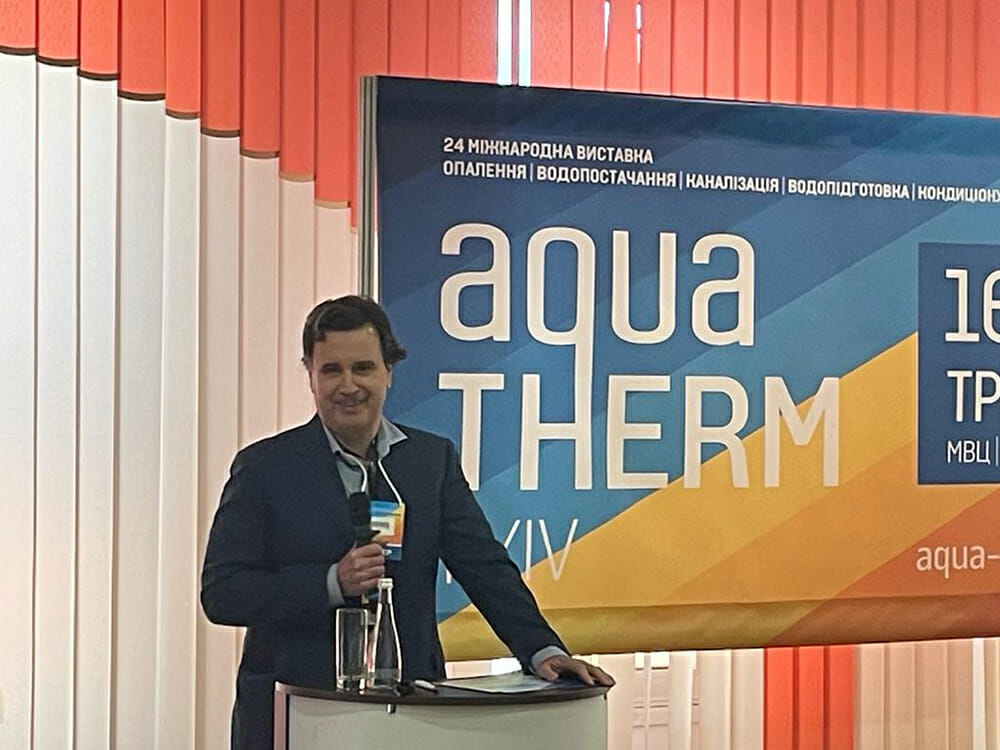

During his most recent visit to Ukraine, Talley was invited to share his knowledge of the industry at several building conferences. His first stop: KyivBuilds.

Bruce Talley, chief financial officer at OFC Inc., speaks at KyivBuilds in May, 2023.

Hosted in Ukraine’s capitol May 16-17, the KyivBuilds conference was attended by over 7,300 people with 161 companies exhibiting. There Talley spoke to a group of Ukrainian mayors, developers, and architects about modular housing. Talley then traveled to Irpin and Zhytomyr to talk about modular building applications in those cities.

“The quality of modular building and the uses are much greater than I realized. Modular building will be in great demand in Ukraine to solve housing,” said Oleksandr Markushin, Mayor of Irpin.

“I learned a lot from Bruce's presentation. I think modular building will be very important for Ukraine's rebuilding,” said Artem Shira, director of Nerex, a water treatment and purification company.

Bruce also presented at the UNation conference in Odesa on May 20, 2023.

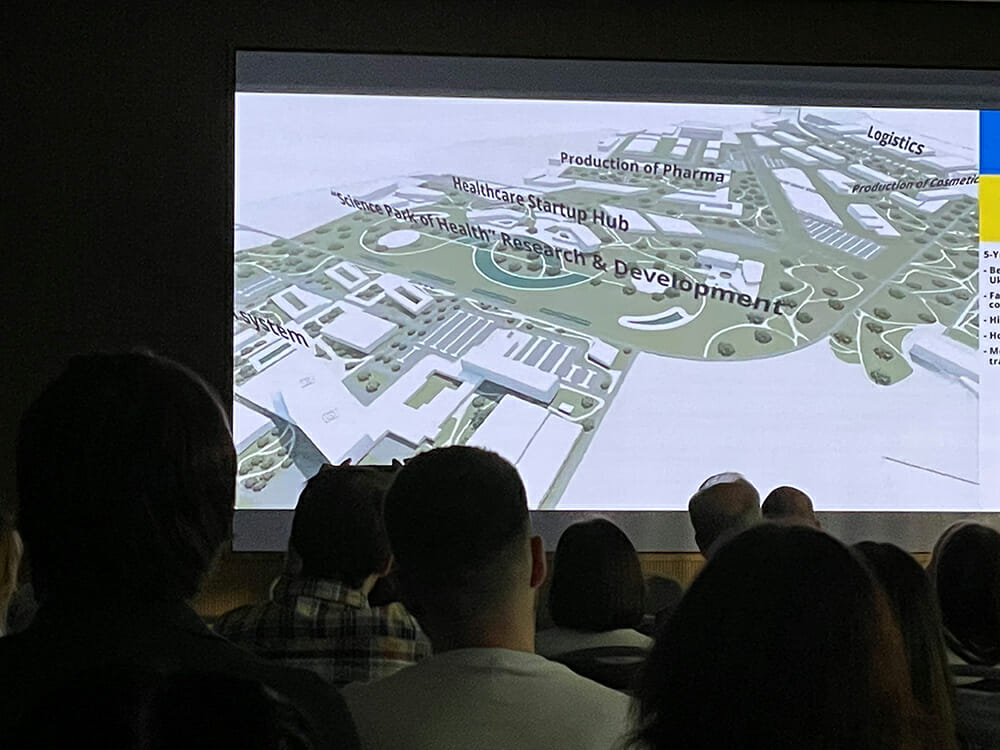

Following his talks in Kyiv, Irpin, and Zhytomyr, Talley attended the UNation conference on May 20th in Odesa. Topics included rebuilding, tech incubators, and the reforms that Ukraine needs to instate to attract foreign investment, as well as regional issues affecting Odesa. Also discussed were several large business parks to be developed in Ukraine, with retail, housing, Olympic training, medical, offices, and redevelopment of an airport.

Related Listening:

Rebuilding Ukraine: What Modular Manufacturers, Dealers, and Developers Need to Know w/ OFC, Inc

Bruce Talley, chief operating officer of OFC Inc., discusses the current conditions inside Ukraine, including the state of its infrastructure and housing, and recounts his personal experience and observations from recent visits. Bruce also shares important information for modular companies looking to help in the relief and rebuilding efforts.

The opportunities for modular construction in Ukraine, it seems, are boundless. But for the industry to make an impact, inroads will need to be made.

“In general,” said Talley, “I’m in Ukraine to meet with people, look at potential production sites (especially in western Ukraine, but not limited to there), and discuss modular housing and container conversion applications for apartments, homes, retail, offices, schools, and hospitals. Everyone is interested in solutions that will save time and money and control costs and outcome. Clearly, employment is driving a lot of thought. However, at each event I have attended that has been a lot of discussion around Smart Cities and sustainable development. So much has been damaged in some areas, that instead of rebuilding like it was, cities will look and work differently with new infrastructure.”

It's early yet to make predictions on when rebuilding efforts can be made in earnest, but Talley sees an opportunity for the global industry to get involved when the time is right. That said, it won’t be a cake walk.

“When we're talking about getting involved in Ukraine, there is a steep learning curve," says Talley. "There are cultural and legal barriers that will be new to many, especially to North American companies. So, it's possible. But if a manufacturer or builder wants to acquire our abilities, our knowledge, our culture, cultural understanding and language skills, and ability to bridge that gap, I think we can do that very well.”

About the Author: John McMullen, PCM, is the marketing director for the Modular Building Institute. You can reach him directly at mcmullen@modular.org or on LinkedIn.

More from Modular Advantage

AI, Faster Sets, and Automation: The Future of Modular is at World of Modular

While the modular building industry has long known that it can be an effective solution to increase affordable housing, the word is slowly spreading to more mainstream audiences. Three presentations at this year’s World of Modular in Las Vegas hope to provide insight and direction for those seeking a real solution to the crisis.

An Insider’s Guide to the 2025 World of Modular

The Modular Building Institute is bringing its global World of Modular (WOM) event back to Las Vegas, and with it comes some of the industry’s best opportunities for networking, business development, and education. Over the course of the conference’s four days, there will be numerous opportunities for attendees to connect, learn, and leverage event resources to get the most out of the conference.

Affordable Housing Now: The Industry’s Best Bring New Solutions to World of Modular

While the modular building industry has long known that it can be an effective solution to increase affordable housing, the word is slowly spreading to more mainstream audiences. Three presentations at this year’s World of Modular in Las Vegas hope to provide insight and direction for those seeking a real solution to the crisis.

Opportunities for Innovation in Modular Offsite Construction

Modular Offsite Construction has already shattered the myth that it only produces uninspired, box-like designs. Architectural innovations in module geometry, configurations, materials, and products make it possible to create visually stunning buildings without sacrificing functionality or efficiency.

Safe Modular Construction with Aerofilm Air Caster Transport

In collaboration with Aerofilm Systems, Heijmans developed innovative skids using air caster technology for moving modules easily and safely. These pallets are equipped with an auto-flow system, making operation extremely simple.

Miles, Modules, and Memes: Building a Modular Network One Flight at a Time

At the end of the day, social media is just another tool for building connections, and like any other tool, needs to be used skillfully to work properly. Use social media thoughtfully, and it will open doors to real opportunities and relationships you didn’t even see coming.

Falcon Structures: Thinking Inside the Box

Some of Falcon’s latest projects include creating container solutions for New York’s Central Park and an East Coast professional baseball team. More and more, Falcon is shipping out container bathrooms and locker rooms to improve traditionally difficult work environments, like those in oil and gas or construction.

UrbanBloc—From Passion to Industry Leader

UrbanBloc specializes in three main categories or markets – what they call “Phase 0” projects, amenities, and urban infill. Clients are often attracted to shipping containers because from a real estate perspective they are considered an asset. Having the flexibility to move and transport these assets allows owners to respond to different circumstances in a fluid manner that they can’t get with standard construction.

The Hospitality Game-Changer

“Hospitality is about more than just providing a service – it’s about delivering an experience,” says Anthony Halsch, CEO of ROXBOX. “And that’s where containers thrive. They allow us to create spaces that are unique, efficient, and sustainable.”

Container Conversions Counts on Simplicity to Provide Critical Solutions

Container Conversions has fabricated and developed thousands of containers for varied projects, including rental refrigeration options, offices, kitchens, temporary workplace housing, and mobile health clinics.