Modular Building is (Almost) as Old as the Hills

About the Author: Anirban Basu is the chairman & CEO of Sage Policy Group and chief economist of the Modular Building Institute.

Quite a History

Many view modular building as the emergent wave in construction. Controlled environments, precision manufacturing, and a highly trained workforce represent the cornerstones of the view that modular methods will continue to garner additional market share as time passes.

But despite its status as an upstart, modular building has been around for centuries. In ancient Rome, armies constructed forts in prefabricated sections.1 They brought those sections with them on their campaigns in order to facilitate easy setup in order to quickly secure newly conquered territory. The Romans are associated with many things, including philosophers, emperors, aqueducts, and stadia. Modular construction forms part of the list.

Fast forward to the 1600s. In Europe, settlers prebuilt homes and fishing houses to be transported as they moved to America. This practice was not unique to America, however. There are reports of structures being shipped from Britain to Australia.

While contemporary modular structures are far more capable than those used by Americans before there was a United States, the basic premise remains the same. By eliminating variables such as temperature and moisture, construction conducted in a controlled setting eliminates many risks, including premature deterioration of construction materials and delays in building as weather systems wreak havoc on conditions.

What is perhaps most remarkable is that, despite these advantages and the realization over the course of centuries that they exist, modular construction continues to be in its infancy from the perspective of construction market share. The industry has been striving for years to attain 5 percent market share in many categories, whether in office or healthcare construction.

In the U.S., Sears, Roebuck, and Co. brought the idea into the 20th century (literally) by offering pre-built homes in its catalog starting in 1908. The idea didn’t take off immediately, but following the Second World War, millions of veterans returned home ready to start a family. Pre-built homes emerged as a major contributor to the rapid spread of household formation and homeownership across the countryside.

Enter the history of Levittown. Starting in 1947, Abraham Levitt commenced work on one of four planned communities, the first of which was situated in Nassau County, Long Island. His son, Alfred, had returned from serving in the war.2 He urged his father to take advantage of a utilitarian approach to construction that had become popular in the U.S. Navy. Serving as chief architect for his father, he designed a simple one-floor home supplemented with an unfinished expansion attic. By the following year, they were producing about 30 houses per day, using materials from their own factories located around the country. The homes were popular. Residents quickly inhabited them. Eventually, the town was used as an archetype of the American Dream, bolstering the popularity of America’s suburbs in the process.

Over the last roughly four decades during which the Modular Building Institute has been in existence (founded 1983), prefabricated construction and modular building have expanded beyond one-floor homes in the suburbs. Today, virtually all major developers are incorporating some element of pre-built units or modules into their projects across both residential and nonresidential segments.

By the 1970s, office buildings, schools, and healthcare facilities were taking advantage of off-site construction to reduce costs and speed up delivery. Prefabrication/modular building has become increasingly popular in other parts of the world as well, including in Australia where such techniques are often used in school construction. The government there has forecasted that the number of students will expand by nearly 59 percent, or by 4 million students by 2051. To match demand to capacity, the government is predictably taking advantage of the development of modular classrooms. Much like modular homes, the classrooms are built off-site, which allows contractors to work around the year without being impacted by weather.

Labor Market Logic

It is well known that the principal challenge faced by many contractors relates to a scarcity of skilled construction workers. With Baby Boomers retiring in larger numbers and many members of the labor force, including younger ones, embracing remote work or gig jobs like driving for Lyft or Uber, shortfalls of skilled workers will plague construction for the foreseeable future.

What’s more, at-the-jobsite construction often requires the participation of local labor forces. But in booming communities like Austin, Nashville, Phoenix, Charlotte, Tampa, and elsewhere, the local labor forces are seldom able to keep up with demand. The competition between project owners to secure the efforts of general and subcontractors drives up costs of construction, which may be good for many contractors, but limits housing and other forms of affordability.

Modular building is fundamentally different. In this instance, construction activity can be divorced from where units will ultimately be delivered. This means that construction can take advantage of the national labor force as opposed to local ones. Moreover, manufacturing facilities serving construction can benefit from enormous economies of scale, reducing costs further as modular techniques continue to acquire construction market share. In short, modular building will likely help solve America’s construction worker shortfall, reducing costs and speeding construction delivery in the process.

This is hardly theoretical. An article published by Construction Dive in 2020 noted that Chick-fil-A, one of the nation’s most popular fast-food establishments, built a restaurant in Roswell, GA in three months using modular techniques. This was significantly faster than the typical 23-week build the chain routinely endures.

The company states that the modular approach “improved efficiency and time savings”, while allowing for “consistency and quality in the fast-food chain’s building across the country.” The article also notes that less waste is produced and that there is less disruption in the surrounding community, which helps to reinforce brand loyalty.

Prefabricated facilities can also limit exposure of harmful chemicals and minimize excess waste. As the world seeks to solve the problem of global warming and to improve public health outcomes, modular techniques represent part of the solution. In the final analysis, modular building has quite a history, but it has an even more spectacular future.

Endnotes

1 Gasc, Marco. “A Brief History on Modular Architecture”. GKV Architects.

2 Jackson, Kenneth T. “The Baby Boom and the Age of the Subdivision”. Ch. 13 from Crabgrass Frontier: The Suburbanization of the United States (New York: Oxford University Press, 1982), 231-245.

More from Modular Advantage

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.

ModMax: Redefining Modular Construction with Confidence and Precision

ModMax was born out of frustration—frustration with five persistent pain points in modular construction: Permitting bottlenecks. Production delays. Rigid designs. Disconnect between “the office” and the field. Lack of transparency and communication.

LifeArk: Disaster-Resilient Housing from Recycled Plastic and 100-year-old Technology

Wee compares LifeArk’s housing units to Yeti coolers, as they are built similarly. Each component takes 15 to 20 minutes to manufacture, has an R-value of 40, and includes molded slots and chases for wiring, plumbing, fire sprinklers, and other utilities.

Building the Future of Modular Edge Infrastructure

The edge data center market is expanding rapidly, driven by the surge in AI workloads, IoT adoption, and the need for localized compute power. In these environments, sustainability, scalability, and reliability are non-negotiable. Cooling is among the most complex challenges for operators—and one of the most decisive factors in long-term success.

Accelerating Light-Gauge Steel Construction: A Semi-Automated Digital Workflow for Off-Site Projects

For construction professionals, the message is clear. By adopting semi-automation and digitalization, companies can deliver projects faster, more accurately, and more profitably, while also building stronger collaboration across teams. The approach is not about replacing people with machines, but about empowering people with better tools and processes.

Why Modular Data Centers Are Gaining Momentum

Artificial intelligence, high-performance computing, and edge applications push the limits of traditional “stick-built” data centers. They take years build, often struggle with high density workloads, and aren’t optimized for deployments near end users. Modular data center platforms are purpose-built to address these challenges, offering flexibility and scalability to adapt to evolving technologies, while opening new opportunities for the modular construction industry.

Supply Chain Innovation in Action: 5 Habits Every Modular Leader Should Practice

By applying these principles to supply chain practices — collaborative planning, strategic procurement, scenario modeling, digital tools, and transparent forecasting — construction leaders can build value chains that are not just efficient and agile, but truly innovative.

Exploring the Role of Modular Integrated Construction (MiC) in Advancing Circular City Principles – A Survey of Stakeholder Perspectives

The survey findings highlight the significant potential of Modular integrated Construction (MiC) in advancing the development of circular cities. By reducing costs, accelerating construction timelines, and minimizing waste generation, MiC offers a promising approach to sustainable urban development.

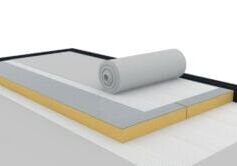

The Use of MS POLYMER™-Based Sealants and Adhesives in Modular Building

These products combine flexibility and elastic recovery with excellent adhesion to different substrates and have already shown their usefulness in traditional construction. Now it’s time for them to be put to use in the modular construction industry.