The Growth of Remote Virtual Inspections

About the Author: Ryan M. Colker is Vice President, Innovation, at the International Code Council.

The COVID-19 pandemic has brought lots of change to the construction industry—particularly for building code and fire safety departments. Most states and the federal government declared code administration and enforcement essential services. However, many departments were faced with the need to implement new policies and procedures to assure their work could continue safely.

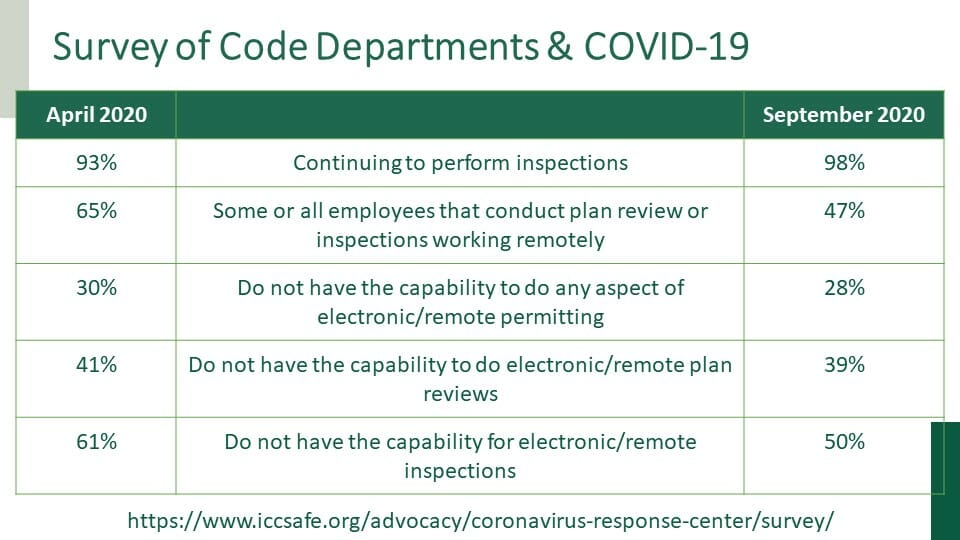

The International Code Council conducted a survey of code departments in March and April of 2020 to gauge their virtual capabilities. Based on over 1,150 responses from all 50 states and Washington, DC, the survey found that the majority of departments (93%) were still doing inspections either remotely or in person. About two-thirds (65%) of jurisdictions reported that some or all employees that conduct plan review or inspections are working remotely. While many jurisdictions made the switch to electronic processes, a large percentage still did not have the capacity to go virtual—for example, 61% did not have the capability to do electronic or remote inspections.1

In August and September 2020, the Code Council again surveyed code departments to see how their processes and practices changed given a little time to adapt. By September nearly all departments were performing inspections (98% versus 93% in April) while nearly half still had key staff working remotely (47% versus 65% in April). In September 53% of departments still did not have the capability to do remote virtual inspections (down from 61% in April).

While remote virtual inspection (RVI) was seen by many as an opportunity to reduce exposure to the virus, many departments were unsure of where to start. Some larger jurisdictions including Los Angeles City and County and North Las Vegas, Nevada already had virtual inspection programs for many small or routine projects and were willing to share their lessons learned with others. Smaller, rural jurisdictions like Miami, Ohio were using remote virtual inspections to cut down on travel times. The Code Council produced a series of documents and held webinars to help provide guidance and get departments up to speed.2 The most recent publication, Model Program for Online Services: Permitting, Plan Review and Remote Inspections, captures best practices from building officials, industry professionals and inspection agencies.3

Remote virtual inspections and off-site construction

The two Code Council surveys primarily captured results in the context of inspections at the job site, but could provide insight into the potential for growth in remote virtual inspections for off-site construction. As code departments become more comfortable with the technology that comfort may spread to state industrialized building programs. The recently released off-site construction standards developed by the Code Council and the Modular Building Institute (MBI) allows for the use of remote virtual inspections at the discretion of the Authority Having Jurisdiction.4

One off-site construction project taking advantage of remote virtual inspection is a 296-room, 105-foot-tall modular citizenM hotel going up in Washington, DC. As COVID-19 threatened to slow construction, the hotel chain, local development manager Altus Realty and third party inspection agency ICC-NTA looked for solutions to mitigate the risk. They approached the District’s Department of Consumer and Regulatory Affairs (DCRA) about the possibility of using remote virtual inspection within the factory in Poland. After a few practice inspections to test out the technology and to ensure DCRA and NTA approved of the procedures, a formal all-virtual inspection process was underway. To assure the same level of quality and compliance as an on-site inspection, NTA personnel developed remote virtual inspection procedures that mirrored NTA’s in-plant inspection procedures and the DCRA Third-Party Program Procedure Manual requirements.

In addition to ramping up the virtual inspection program at NTA the manufacturer also needed to prepare for the virtual inspection process. Quality assurance personnel were assigned to assist with inspections. In advance of the inspection on-site personnel provide NTA with copies of all material listings for each module. During the inspection plant personnel show the serial number for the unit being inspected and walk through an inspection checklist with the NTA inspector. Close ups or more focused videos can be requested by the NTA inspector.

Using the remote virtual inspection process NTA inspectors can monitor testing of modules including water testing of window installation, pressure testing of plumbing systems and other important procedures.

While it took some getting used to for the inspectors, a good rapport with the quality assurance personnel in the factory and comfort on the part of DCRA with the protocols put in place by NTA, the remote virtual inspection process provided some valuable lessons for the project team and may open opportunities for further use of remote virtual inspections in the future.

Endnotes

1 International Code Council, Building Safety and COVID-19: Analysis of U.S. Code Department Responses to the Pandemic. July 1, 2020. https://www.iccsafe.org/wp-content/uploads/20-18952_GR_Survey_Analysis_RPT_FINAL_HIRES.pdf

2 See https://www.iccsafe.org/advocacy/coronavirus-response-center/virtual/ for access to virtual resources.

3 International Code Council, Model Program for Online Services: Permitting, Plan Review and Remote Inspections. April 2021. https://shop.iccsafe.org/model-program-for-online-services-permitting-plan-review-and-remote-inspections.html

4 ICC/MBI 1205-2021 Standard for Off-Site Construction: Inspection and Regulatory Compliance, Section 301.2. https://codes.iccsafe.org/content/ICC12052021P1/chapter-3-plan-approvals-and-inspection-procedures

More from Modular Advantage

An Insider’s Guide to the 2025 World of Modular

The Modular Building Institute is bringing its global World of Modular (WOM) event back to Las Vegas, and with it comes some of the industry’s best opportunities for networking, business development, and education. Over the course of the conference’s four days, there will be numerous opportunities for attendees to connect, learn, and leverage event resources to get the most out of the conference.

Affordable Housing Now: The Industry’s Best Bring New Solutions to World of Modular

While the modular building industry has long known that it can be an effective solution to increase affordable housing, the word is slowly spreading to more mainstream audiences. Three presentations at this year’s World of Modular in Las Vegas hope to provide insight and direction for those seeking a real solution to the crisis.

Opportunities for Innovation in Modular Offsite Construction

Modular Offsite Construction has already shattered the myth that it only produces uninspired, box-like designs. Architectural innovations in module geometry, configurations, materials, and products make it possible to create visually stunning buildings without sacrificing functionality or efficiency.

Safe Modular Construction with Aerofilm Air Caster Transport

In collaboration with Aerofilm Systems, Heijmans developed innovative skids using air caster technology for moving modules easily and safely. These pallets are equipped with an auto-flow system, making operation extremely simple.

Miles, Modules, and Memes: Building a Modular Network One Flight at a Time

At the end of the day, social media is just another tool for building connections, and like any other tool, needs to be used skillfully to work properly. Use social media thoughtfully, and it will open doors to real opportunities and relationships you didn’t even see coming.

Falcon Structures: Thinking Inside the Box

Some of Falcon’s latest projects include creating container solutions for New York’s Central Park and an East Coast professional baseball team. More and more, Falcon is shipping out container bathrooms and locker rooms to improve traditionally difficult work environments, like those in oil and gas or construction.

UrbanBloc—From Passion to Industry Leader

UrbanBloc specializes in three main categories or markets – what they call “Phase 0” projects, amenities, and urban infill. Clients are often attracted to shipping containers because from a real estate perspective they are considered an asset. Having the flexibility to move and transport these assets allows owners to respond to different circumstances in a fluid manner that they can’t get with standard construction.

The Hospitality Game-Changer

“Hospitality is about more than just providing a service – it’s about delivering an experience,” says Anthony Halsch, CEO of ROXBOX. “And that’s where containers thrive. They allow us to create spaces that are unique, efficient, and sustainable.”

Container Conversions Counts on Simplicity to Provide Critical Solutions

Container Conversions has fabricated and developed thousands of containers for varied projects, including rental refrigeration options, offices, kitchens, temporary workplace housing, and mobile health clinics.

Revelution Containers and S. I. Container Builds: On a Mission to Revelutionize Housing

Rory Rubun and Pam Bardhi are on a mission to create more housing. Together, they plan to build shipping container eco communities similar to single-family subdivisions, and mixed-use buildings in urban settings. They also want to expand the footprint of ADUs across the nation.