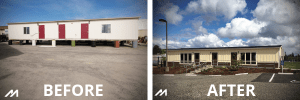

Repurposed for a Second Life: Renovated Reuse Case Study

The original 24’x64’ building was built by Modern Building Systems in 1996 to serve as daycare facility for the Northwest Regional Educational Service District (ESD) in Forest Grove, Oregon. In 2016 the building was no longer needed and donated to the local Habitat for Humanity chapter by Modern Building Systems. They purchased and removed the building at no cost to the ESD. It then was transformed into a beautiful newly renovated daycare facility for Family Nurturing Center to expand services as a satellite campus in Phoenix, Oregon. The building now houses daycare services for 28 children and families.

The newly renovated daycare space is comprised of two classrooms, men’s and women’s restrooms, an office space, and kitchen. Modern worked with Family Nurturing Center board member and architect, Brian Westerhout to redesign the building to fit the needs and desires of the daycare. Additional walls were installed near the restroom and hallway area between the classrooms was widened to allow for greater accessibility. Old windows were replaced by large 8/0 x 6/0 premium vinyl windows to bring in more sunlight into the room. While the upgrades of marmoleum flooring and casework adds additional visual appeal throughout the building. The new exterior features include: bright custom colors of fiber cement siding and trims. Roofing and welded hollow metal doors were upgraded as well.

Materials from the original builder were used whenever possible. By utilizing the original structure as much as possible, the result was less construction and demolition waste in the landfill. Basically, the client recycled a whole modular building. A brand new high-efficient gas Bard mechanical unit was installed on the building to upgrade the building.

The Family Nurturing Center is a nonprofit that is part of Oregon’s innovative and comprehensive response to support children and families in crisis and therefore operates on razor thin budgets. Modern, long with local contractors, gave discounts and donations to help make this project a reality. By utilizing a used building and renovating it, the client saved thousands of dollars compared to a new building to the same design and specifications.

This article originally appeared in the Modular Advantage Magazine - Fourth Quarter 2018 released in November 2018.

More from Modular Advantage

AI, Faster Sets, and Automation: The Future of Modular is at World of Modular

While the modular building industry has long known that it can be an effective solution to increase affordable housing, the word is slowly spreading to more mainstream audiences. Three presentations at this year’s World of Modular in Las Vegas hope to provide insight and direction for those seeking a real solution to the crisis.

An Insider’s Guide to the 2025 World of Modular

The Modular Building Institute is bringing its global World of Modular (WOM) event back to Las Vegas, and with it comes some of the industry’s best opportunities for networking, business development, and education. Over the course of the conference’s four days, there will be numerous opportunities for attendees to connect, learn, and leverage event resources to get the most out of the conference.

Affordable Housing Now: The Industry’s Best Bring New Solutions to World of Modular

While the modular building industry has long known that it can be an effective solution to increase affordable housing, the word is slowly spreading to more mainstream audiences. Three presentations at this year’s World of Modular in Las Vegas hope to provide insight and direction for those seeking a real solution to the crisis.

Opportunities for Innovation in Modular Offsite Construction

Modular Offsite Construction has already shattered the myth that it only produces uninspired, box-like designs. Architectural innovations in module geometry, configurations, materials, and products make it possible to create visually stunning buildings without sacrificing functionality or efficiency.

Safe Modular Construction with Aerofilm Air Caster Transport

In collaboration with Aerofilm Systems, Heijmans developed innovative skids using air caster technology for moving modules easily and safely. These pallets are equipped with an auto-flow system, making operation extremely simple.

Miles, Modules, and Memes: Building a Modular Network One Flight at a Time

At the end of the day, social media is just another tool for building connections, and like any other tool, needs to be used skillfully to work properly. Use social media thoughtfully, and it will open doors to real opportunities and relationships you didn’t even see coming.

Falcon Structures: Thinking Inside the Box

Some of Falcon’s latest projects include creating container solutions for New York’s Central Park and an East Coast professional baseball team. More and more, Falcon is shipping out container bathrooms and locker rooms to improve traditionally difficult work environments, like those in oil and gas or construction.

UrbanBloc—From Passion to Industry Leader

UrbanBloc specializes in three main categories or markets – what they call “Phase 0” projects, amenities, and urban infill. Clients are often attracted to shipping containers because from a real estate perspective they are considered an asset. Having the flexibility to move and transport these assets allows owners to respond to different circumstances in a fluid manner that they can’t get with standard construction.

The Hospitality Game-Changer

“Hospitality is about more than just providing a service – it’s about delivering an experience,” says Anthony Halsch, CEO of ROXBOX. “And that’s where containers thrive. They allow us to create spaces that are unique, efficient, and sustainable.”

Container Conversions Counts on Simplicity to Provide Critical Solutions

Container Conversions has fabricated and developed thousands of containers for varied projects, including rental refrigeration options, offices, kitchens, temporary workplace housing, and mobile health clinics.