Modular Advantage Magazine

In each bi-monthly issue, Modular Advantage magazine explores a specific modular construction topic and features interviews and articles from industry experts along with news and updates from the Modular Building Institute and its members, modular building case studies, and upcoming industry events. This construction trade magazine is an invaluable resource for anyone interested in the global commercial modular and relocatable buildings industry.

Printed copies are free to MBI members and include exclusive content not available anywhere else. The abridged, digital versions of each issue, available below, are available free for everyone.

Not an MBI member? That's okay!

Start your subscription to Modular Advantage magazine today and discover the latest in modular construction.

Latest Articles & Interviews

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

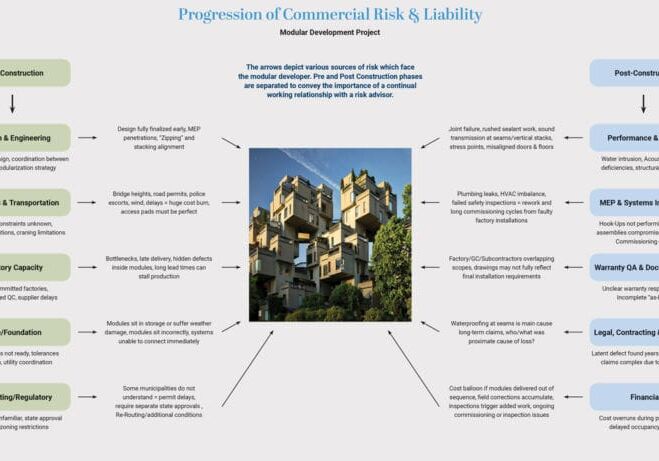

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

SPONSORED BY

Featured Modular Building Case Studies

Pomeroy Employee Housing

The Pomeroy Lodging Employee Housing complex in Kananaskis, AB, is a 24,194 sq. ft., three-story structure with 57 studio units and a communal main-level area, designed for full-time employees and comprised of 36 prefabricated modules.

Scalable & Smart EV Charging Containers

NexE, the green energy sister company of TECO-Westinghouse, partnered with Falcon Structures to design and build portable enclosures for EV fleet operators interested in re-deployable units that support EV charging depots with significant cost savings. The goal: create durable, relocatable EV infrastructure solutions that sidestep the constraints of traditional construction.

732 El Camino Real

Each living unit at 732 El Camino Real was built in the Autovol plant by a combination of robots and Autovol’s skilled builders. Work was completed for all 134 units in 51 days. The living units left the factory as fully functioning apartments—approved in factory by California inspectors to meet all applicable codes.

Heat-Resistant Equipment Enclosure for Industrial Ovens

To house the end customer’s industrial-strength ovens, Panel Built created over 400 heat-resistant panels, each built to exact specifications and clearly labeled for straightforward placement. Panel heights ranged between 7 and 9 feet, with a uniform thickness of 3.75 inches.

LIFE Senior Services

The installation of Solatube TDDs in the new recreation facility successfully met the project’s goals for daylighting, comfort and functionality. The space which houses indoor pickleball and basketball is now naturally illuminated with bright, evenly distributed daylight that enhances visibility and supports safe movement for senior users.

Faster, Smarter, Custom-Built: A New Era of Student Housing

Modular Genius delivered a 25,000+ square foot modular student housing complex made up of 22 buildings to Catholic University: 19 cottage-style units and two larger traditional hall-style dormitory buildings, totaling 124 student beds.

Building Hope: ROC Modular’s Role in the Steveston Highway Affordable Supportive Housing Project

At ROC Modular, we knew this was the kind of project where modular construction could make a real difference. By fabricating the building in modules offsite and assembling them on location, we could cut down construction time significantly while maintaining the high standards required by BC Housing and CMHC Universal

Design Guidelines.

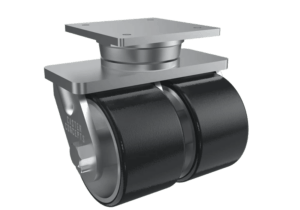

How Caster Concepts Redefined Durability in Modular Construction

Frequent failures, high maintenance, and operational slowdowns became a challenge that Autovol wanted to solve as quickly as possible. The solution to the problem was Caster Concepts’ ten 81 Series Kingpinless Heavy-Duty Casters, each rated to handle over 10,000 lbs.

Midland Apartments

The Midland Apartments in Buena Vista, Colorado, are a standout example of how innovative thinking and collaboration can solve housing challenges. A key to the project’s success was its use of offsite modular

construction.

FlexDecks Provides Modular Egress Access to Omaha Custom Manufacturing

FlexDecks provided a modular system, RightWay Pro, which allowed for configuration and quoting within hours. Simple step by step instructions helped

the facilities team assemble the system within a single day, while FlexDecks provided install supervision for peace of mind.

Safe Modular Construction with Aerofilm Air Caster Transport

In collaboration with Aerofilm Systems, Heijmans developed innovative skids using air caster technology for moving modules easily and safely. These pallets are equipped with an auto-flow system, making operation extremely simple.

Building the Future: Triumph Modular’s Construction Services Team and Their Summer 2024 Masterpiece

In the summer of 2024, Triumph Modular’s Construction Services team undertook one of its most ambitious projects: $306 million modular construction initiative for the Manchester Public School system in New Hampshire.

Wilmot Modular Structures, Inc. Corporate Campus

Wilmot required a modern, efficient headquarters to showcase their modular construction expertise while fostering team collaboration and innovation. The facility was designed to streamline operations, reflect the company’s commitment to sustainability, and support long-term growth under multigenerational leadership.

Castlegar Student Housing, Selkirk College

Modular construction was chosen as the ideal solution to provide high-quality, fast-track affordable housing for students, delivering a 3-storey, 30-module, 114-student bed building with a mass-timber main common

area for student amenities.

Manchester Public Schools Temporary Classroom Space

The buildings can accommodate up to 1,000 students during construction of permanent buildings, allowing education to proceed without interruption. The modern and fully equipped modular learning spaces ensure a smooth transition for both students and staff.

Oldivai on 31st – Modular Housing, Rinse and Repeat

With a “kit-of-parts” approach, Oldivai on 31st demonstrated how a predesigned layout could deliver consistent programming and rapid deployment.

Hawthorn Extended Stay by Wyndham—Jackson, WY

The plan was to build the project in two phases. This would enable the property to open sooner and start

accommodating guests while completing the second phase. The digital twin was designed to provide a complete factory-ready model for both phases upfront. That gave the factory everything it needed to bring each phase into production quickly. It also enabled everyone a way to plan both

phases ahead of time, and begin prepping the site in advance.

102-108 Westford Street

102-108 Westford was an opportunity for New England-based GreenStaxx to show how project costs could be trimmed by using a standardized, modular-ready Triple Decker design.

Geberit In-Wall Systems Makes a New Breed Luxury Room Concept a Reality for International Hotel Brand

Geberit in-wall flush toilet systems for wall-hung toilets are the classics for modern bathroom design. citizenM has specified the Geberit systems into their bathroom walls worldwide as a basis of their bathroom design. This installation is part of the over one million times building owners have installed Geberit systems in their buildings around the globe for over the past 50 years.

Panel Built Provides Custom Modular Enclosure for Major Beverage Manufacturer

The challenge was twofold. Firstly, Panel Built needed to create a spacious enclosure that could accommodate a large facility crane. This enclosure required a design that provided ample storage space and integrated seamlessly with the existing infrastructure. Secondly, the structure needed to incorporate office space that offered personnel an unimpeded, 360-degree view of the factory floor.

Currently an MBI member? Submit your case studies for publication today!

Online Exclusives

Recent Issues

Past Articles & Interviews

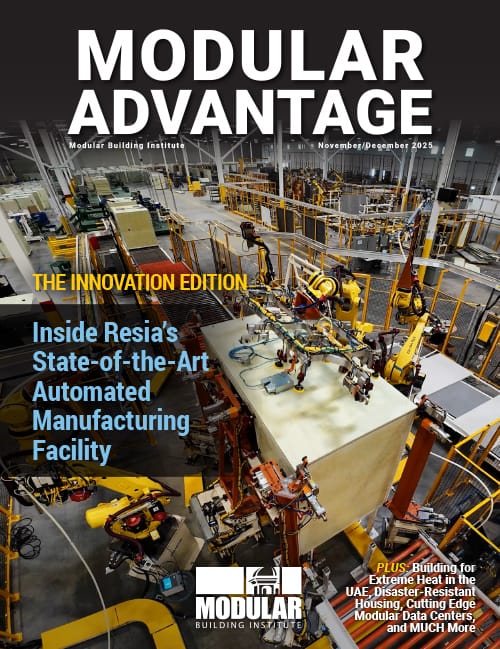

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.

ModMax: Redefining Modular Construction with Confidence and Precision

ModMax was born out of frustration—frustration with five persistent pain points in modular construction: Permitting bottlenecks. Production delays. Rigid designs. Disconnect between “the office” and the field. Lack of transparency and communication.

LifeArk: Disaster-Resilient Housing from Recycled Plastic and 100-year-old Technology

Wee compares LifeArk’s housing units to Yeti coolers, as they are built similarly. Each component takes 15 to 20 minutes to manufacture, has an R-value of 40, and includes molded slots and chases for wiring, plumbing, fire sprinklers, and other utilities.

Building the Future of Modular Edge Infrastructure

The edge data center market is expanding rapidly, driven by the surge in AI workloads, IoT adoption, and the need for localized compute power. In these environments, sustainability, scalability, and reliability are non-negotiable. Cooling is among the most complex challenges for operators—and one of the most decisive factors in long-term success.

Accelerating Light-Gauge Steel Construction: A Semi-Automated Digital Workflow for Off-Site Projects

For construction professionals, the message is clear. By adopting semi-automation and digitalization, companies can deliver projects faster, more accurately, and more profitably, while also building stronger collaboration across teams. The approach is not about replacing people with machines, but about empowering people with better tools and processes.

Why Modular Data Centers Are Gaining Momentum

Artificial intelligence, high-performance computing, and edge applications push the limits of traditional “stick-built” data centers. They take years build, often struggle with high density workloads, and aren’t optimized for deployments near end users. Modular data center platforms are purpose-built to address these challenges, offering flexibility and scalability to adapt to evolving technologies, while opening new opportunities for the modular construction industry.

Supply Chain Innovation in Action: 5 Habits Every Modular Leader Should Practice

By applying these principles to supply chain practices — collaborative planning, strategic procurement, scenario modeling, digital tools, and transparent forecasting — construction leaders can build value chains that are not just efficient and agile, but truly innovative.

Exploring the Role of Modular Integrated Construction (MiC) in Advancing Circular City Principles – A Survey of Stakeholder Perspectives

The survey findings highlight the significant potential of Modular integrated Construction (MiC) in advancing the development of circular cities. By reducing costs, accelerating construction timelines, and minimizing waste generation, MiC offers a promising approach to sustainable urban development.

Share Your Story

Do you have a new product, innovative project, or interesting industry news? We want to hear from you! Submit content and inquiries to our communications team at communications@modular.org.

*Not all content submitted will be used. MBI reserves the right to choose content.