Developing the Offsite Workforce

Heather Wallace is the Director of Communications / Project Manager at Momentum Innovation Group, LLC.

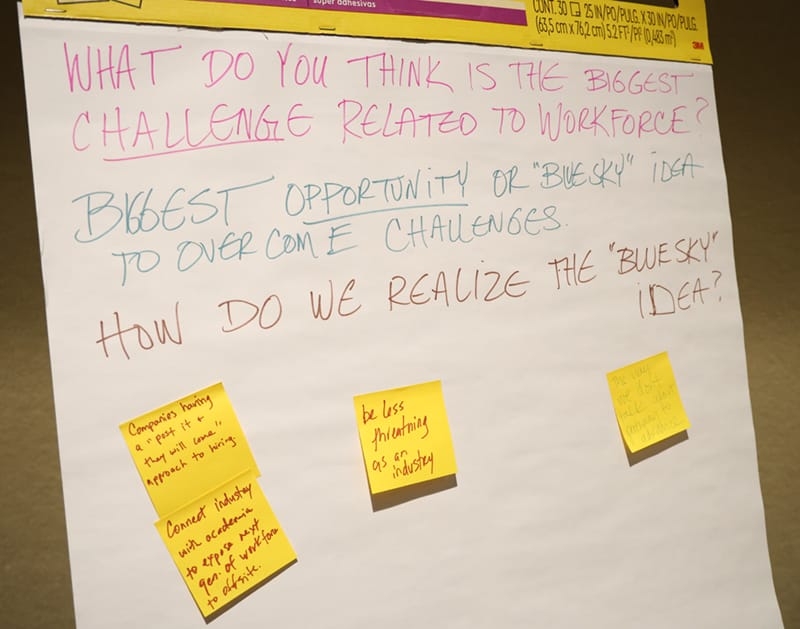

Workforce development and labor challenges continue to be a topic of discussion and area of opportunity for the construction industry, and during the 2024 World of Modular conference in Orlando, The Workforce Development Lounge (“The Lounge”), hosted by Momentum Innovation Group, was launched to provide a space for attendees to network and collaborate on labor solutions and resources. The Lounge supported ongoing efforts, as well as new ones, like MBI’s Modular Advocacy Program (“MAP”) that is aiming to drive industry growth and attract new employees to the modular industry.

Some of the most discussed topics in The Lounge revolved around the need to update Human Resources and hiring practices, increasing exposure and training resources for offsite education at all levels of learning, and workplace culture.

Education and Training

General contractors, new to modular construction, were on the hunt for presentations that might help answer questions about how to efficiently and effectively get started in the offsite industry. The Lounge proved to be a fruitful space to connect GC’s with other organizations to teach, learn, and collaborate. If we want to grow our industry we need to consistently create easily accessible training resources and make sure we are making space for this type of learning at offsite conferences.

Pittsburgh-based Module has been working on training standards since their launch of the Last Mile Network that includes the manufacturers, architects, transporters, and GC’s who are trained on the MODULE building system. The resulting training manual, the Off-Site Construction Playbook, includes sections on Design & Pre-Construction, Site and Set Day Prep, On-Site MEP Connections and Completion, and Post-Set On-Site Finish Work. Module is now helping other companies create their own Playbooks.

Third party staffing solutions were a topic of conversation as well. Both 4A Constructs and 4Ward Solutions Group were able to connect companies interested in utilizing their resources including Tunnel to Towers Foundation - a nonprofit organization based in New York. Tunnel to Towers was in attendance for the first time and was eager to get connected to third party labor solutions, factories, and other companies interested in job placement opportunities for Veterans across the country.

FourA, an experienced general contracting firm, is focused on providing modular builders a one stop shop for skilled labor needs. “Our team consists of experts with multiple years of construction experience and are trained to identify top craft workers who are reliable, verifiably skilled and safety-minded,” says founder Trey Shelton. “The benefit we bring to modular builders is an increase in production, extensive skilled labor, and onsite management.”

4Ward offers comprehensive services and products that provide businesses with expert guidance and support for all offsite operations including lean management, business solution software, resource optimization through Digital Twins, workforce development, component design, automated equipment and more. Their labor solutions offer general construction labor as well as specialty skilled and trained individuals such as purchasers, designers, and equipment operators. Additionally, they have a temporary management service that can provide interim leadership to fill critical roles while searching for permanent solutions.

Affinity Modular, a Vantem Company, is putting offsite in front of residents at the Valdosta Transitional Center (VTC) through the Georgia Department of Corrections. As one of 13 programs like this across the state of Georgia, VTC is producing a skilled workforce for landscaping, maintenance, carpentry, roofing, plumbing, HVAC, mechanics, food service, equipment operations, janitorial, and other general labor. Affinity currently employs seven men from the VTC program.

Early Exposure and Outreach

Increasing early exposure to offsite construction must start earlier in the education process.

4Ward Solutions Group offers many training and staffing operations for the offsite industry. (Photo: 4Ward Solutions Group)

Boise-based company, Modular Maven, has found success in using “proven practices” to create meaningful tours for students including enough time for Q&A, and qualifying tours to understand ages and interests and making sure students are able to spend time in those areas. For example, if touring students are interested in design, make sure they get a quick meet-and-greet with your design team. Follow-up and clear communication with teachers is also an important part of bringing education and industry together to build the future workforce.

Tremco’s Rising Stars Program brought local high school students to World of Modular for a second year in a row. The Rising Stars Program has been successful in empowering young people to discover sustainable careers in the construction industry and the program was recently honored with the National Institute of Building Sciences Diversity, Equity, and Inclusion Award. To date, the program has graduated 80 students and operates in Brooklyn, Newark, Boston, Charlotte, and Cleveland (Fall 2024).

Tremco’s Rising Stars program brought local high school students to MBI's 2024 World of Modular. (

Culture is Key

Workplace culture was also a widely discussed topic during the conference - specifically on how culture affects diversity at all levels. Increasing the number of women in construction (currently ~11%) is just one aspect of diversity and good company culture has to clearly provide pathways for all employees to grow and advance.

“We actually don’t have a diversity and inclusion policy,” says Merrick Macomber, Chief Culture Officer at Autovol. “We hire off of character, not pedigree. We have mentors, not bosses. I’m inspired to come to work each day and to know there’s a pathway forward for [all our employees].”

2023 was the first time in history that over 10% of Fortune 500 companies were led by women - even though they make up 47.5% of the labor force and are 33% more likely to gain a college degree than men.

Deanna Savage, VP of Construction at the Preservation of Affordable Housing adds that just putting someone in a position is not enough. “It’s not only about who’s at the table and who’s missing, but how do you keep the people who have been invited to the table to stay? If you’re at that table, make sure they are allowed to speak and that they are not only invited because of who they are and where they came from, but because you want to hear their voice.”

Human Resources plays a large role in effective hiring and if your HR team isn’t quite sure what is happening on the plant floor or how exactly those modules are transported, they may have a difficult time weeding through applicants. Some manufacturers are beginning to offer their HR teams more exposure to what each position entails - that may mean they spend time on the plant floor, participate in a ride along with the transport team, talking in depth with the designers and engineers, or watching a set - exposure to all areas of the offsite process will allow them to create better job listings and find the best fit for openings.

Taking into consideration all the feedback from attendees we hope to see The Lounge up and running again in 2025 in Vegas but until then, what area will you and your company be focusing on to improve the training, education and culture for our future workforce?

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.